The Demands of Spacecraft Landing Hardware

- Withstanding shock loads from impact and deceleration

- Maintain structural continuity under high stress

- Ensure alignment for recovery systems like airbags and struts

- Deliver documented performance for qualification and flight readiness

Examples of Components We Can Manufacture

- Spacecraft Load-distribution brackets and mounts

- Structural dampening hardware

- Space Capsule landing frames and recovery supports

- Mounting bases or airbag integration

How Oberg Meets the Challenge

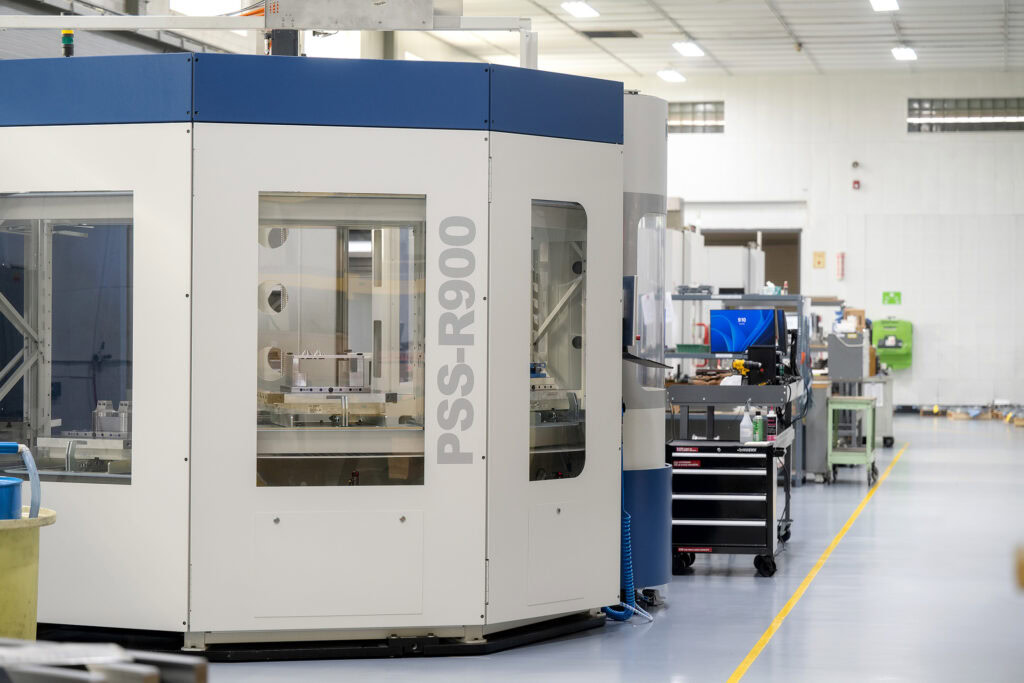

Landing hardware requires scale, accuracy, and rugged repeatability. Oberg brings all three.

- Large-Format 5-Axis Machining – DMG MORI DMC 210 Portal and Grob equipment handle oversized landing frames and impact structures with tight-tolerance accuracy

- Material Expertise – Titanium, Stainless, A286, and aerospace-grade aluminum alloys to name a few. Customer specified

- Edge Blending & Stress Reduction – Multi-surface machining and finishing to minimize stress concentrations at critical interfaces

- Large-Format CMM Inspection – Every bracket, mount, and frame validated for bolt locations, flatness, and geometry control

- Secondary Treatment Prep – Surface prep for coatings, plating, or bonding to meet mission-specific requirements

Ground Contact, Manufactured to Hold to Your Engineered Tolerances

From reentry vehicles to landing capsules, Oberg Industries can manufacture the spacecraft landing components that you design to protect payloads, crews, and ensure mission success at the moment of recovery. Whether you need single test articles or production-scale landing structures, we provide the machining and inspection capacity to deliver with confidence.

Contact us. Let’s manufacture the hardware that helps your spacecraft stick the landing.