Innovators in the field

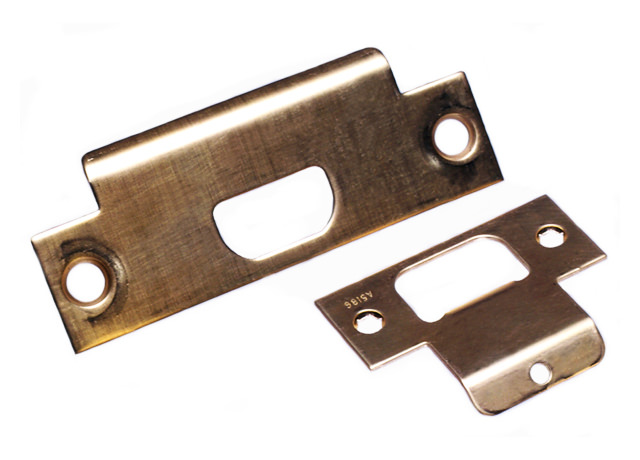

Oberg pioneered the industry’s original high-volume, high-precision tooling design that is still used today to make most metal parts and assemblies for the housing / construction market. Our tooling expertise optimizes material utilization, part production rate, and equipment up-time to give you smarter, more cost-efficient, high-volume solutions.

Full-Service Supplier

Oberg has both capacity and logistics to handle large projects. Our project managers and manufacturing engineers can quickly transfer your large stamping projects at other suppliers over to our manufacturing facilities – with the ability to combine stamping, fastening, finishing, in-process inspection and product assembly. We work with you on long term supply contracts, volume-based pricing, and inventory stocking programs.

A Track Record of Success

With our legacy of designing and producing high-performance progressive stamping dies and a facility with over 50 stamping presses, Oberg delivers the die engineering and part production needed for your project. It’s why you will find our precision metal components and assemblies in millions of homes and offices worldwide.