Antenna Components We Can Manufacture

Oberg can machine a wide range of antenna component types used in orbital, launch, and satellite communication systems. Our machining capabilities, when applied to your designs, meet the tight tolerances, thermal stability, and signal-critical geometry your applications require.

- Low-expansion antenna mounts

- RF and EMI-shielded housings

- Waveguide flanges and microwave interface frames

- Sensor brackets and vibration-isolated baseplates

Antenna Components Manufactured for Performance Across Every Frequency

We work with customer specified aerospace-qualified materials and post-processing methods specified for aerospace applications, supporting your design requirements for interference control and reliability.

- Titanium, Inconel®, Copper Alloys, 15-5 Stainless, Aerospace Aluminum

- Machining for precise fit, minimal signal loss, and clean surface interfaces

- Post-processing to reduce EMI, outgassing, and surface contamination

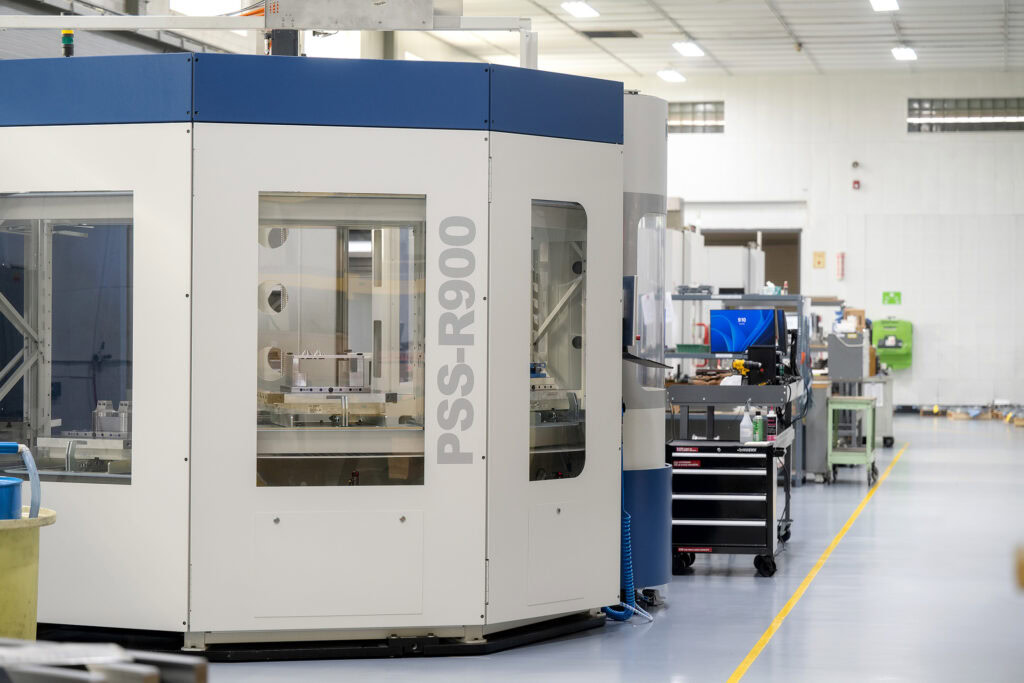

Focused on Manufacturing Readiness

From small threaded connectors to complex waveguide assemblies, Oberg provides precision machining backed by rigorous validation:

- Swiss turning for threaded connectors and miniature interfaces

- Multi-axis milling and EDM for internal and external signal paths

- Polishing and deburring to protect fragile ports and contacts

- Inspection using CMM, optical systems, and feature-specific tools

Partner with Oberg for Communication Reliability

When your mission depends on signal clarity, every mechanical component matters. Oberg provides the manufacturing expertise to produce antenna hardware to your design intent, with documented precision and repeatability that aerospace programs require.

Let’s connect. Contact us to discuss how Oberg can support your next antenna system build.