Razor Blade Tooling Applications We Support:

- Personal Care Razor Blades – Cartridge and disposable razor blade tooling for grooming products

- Surgical & Medical Blades – Built for sterile environments and dimensional accuracy

- Industrial Cutting Blade Tools – Specialty blades and tooling for heavy-duty material applications

What Sets Our Razor Blade Tooling Apart:

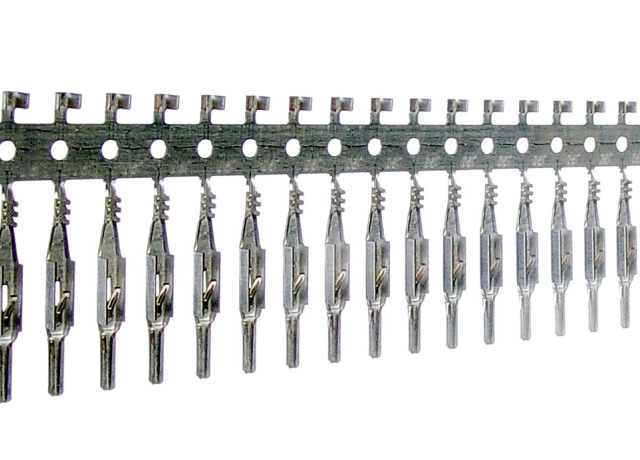

- Ultra-Precision Grinding – Consistent blade profiles with repeatable blade edge control

- High-Durability Materials – Tool steels and alloys engineered to resist wear and distortion

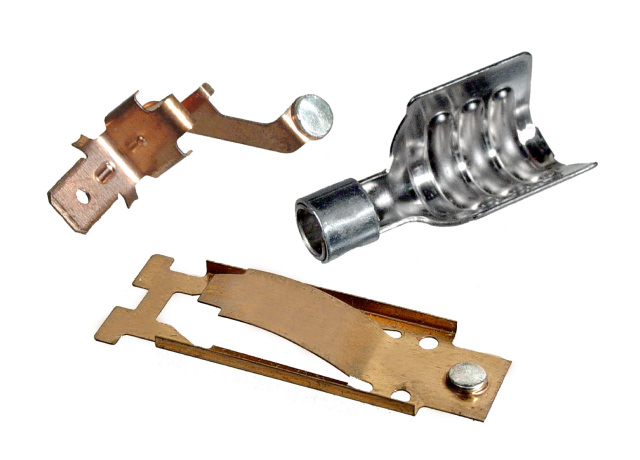

- Custom Die Solutions – Designed for a wide range of blade geometries and edge profiles

- Surface Finishing & Coating Options – Low-friction finishes and corrosion protection

Supporting Scalable Razor Blade Production at Every Stage

Whether you’re launching a new product or scaling an existing blade line, Oberg offers:

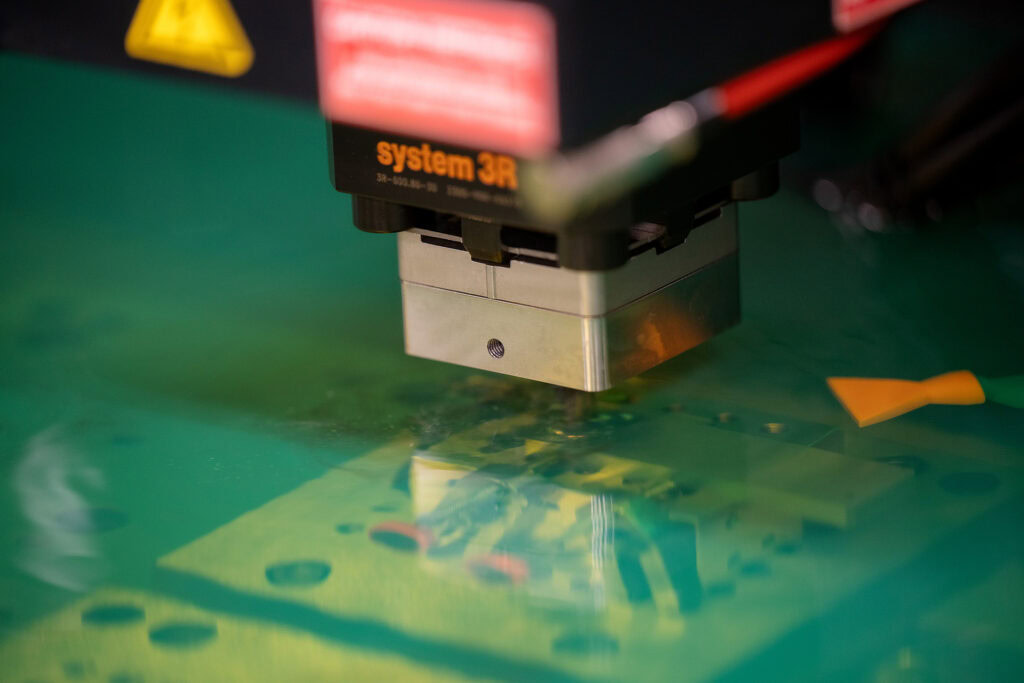

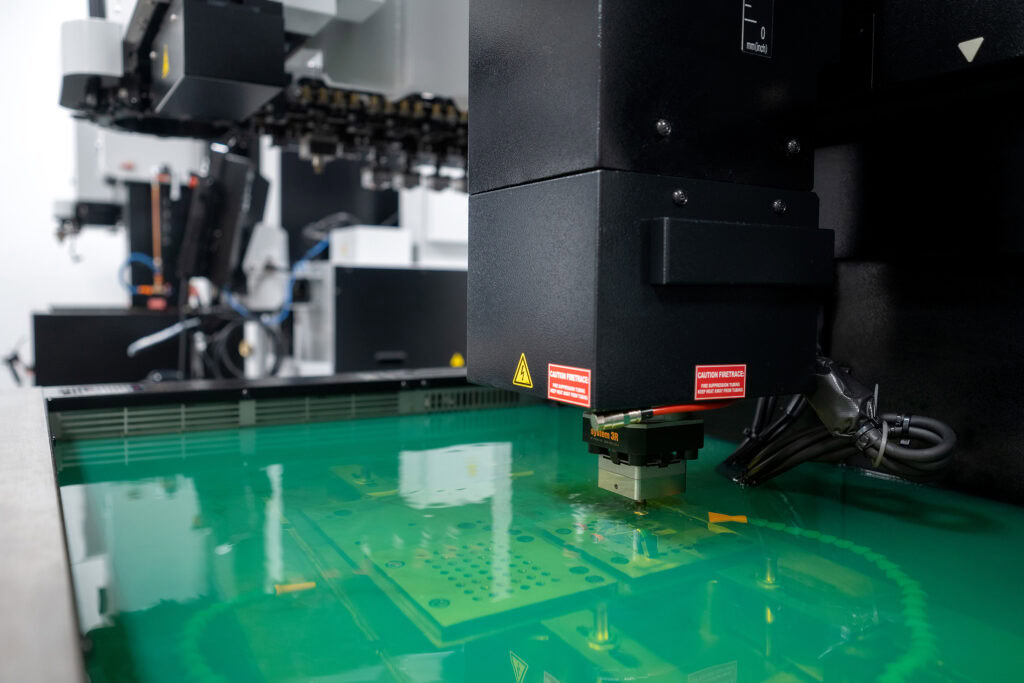

- Wire EDM and tool assembly for exacting blade die builds

- Multi-station carbide dies for long-run reliability

- Prototyping support and low-volume test runs

- Short-run or full-scale production of blade components upon request

Domestic Strength with a Sharpened Edge

From our Western Pennsylvania headquarters and with additional support for medical blade manufacturing through our facilities in Chicago, IL, and Wallingford, CT – Oberg provides North American razor blade manufacturers with tooling support that improves line efficiency and product consistency. We help teams move faster from concept to output with tight control over razor blade tool design and validation.

Better Razor Blade Tooling. Better Razor Blades.

Oberg Industries brings decades of innovation in grinding and die manufacturing to razor blade tooling.

Contact us to discover how we can support your next edge-critical product.