What Makes Our Modular Stamping Dies Effective:

- Interchangeable Modules – Adapt dies for new parts without complete die replacement

- Engineered for Repeatability – Built for consistency and accuracy across cycles

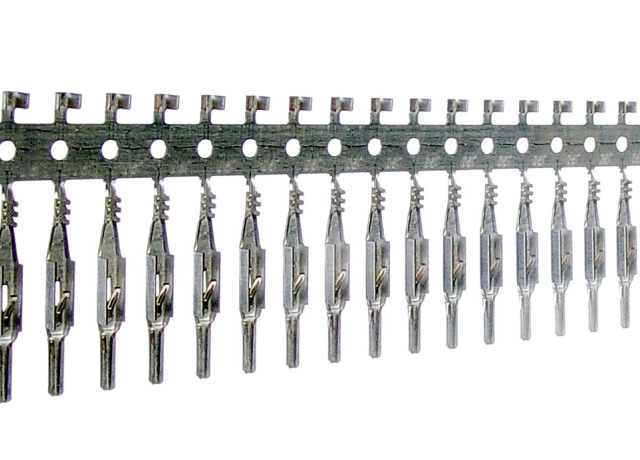

- Supports Multi-Stage Operations – Ideal for progressive stamping, in-die tapping, and in-die assembly

- Built to Last – Constructed from high-durability materials with wear-resistant coatings

Industry Applications:

- Consumer & Industrial Hardware – Appliance panels, enclosures, and structural parts

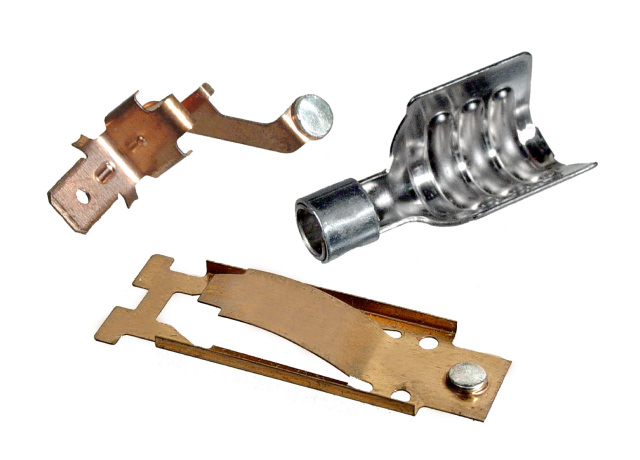

- Automotive & EV Systems – Stamped components for electrical routing and chassis structures

- Medical Components – Compact precision dies for small-format, surgical-grade parts

- Electronic Devices – Die solutions for high-speed contact and circuit stamping

Advanced Die-Making Capabilities

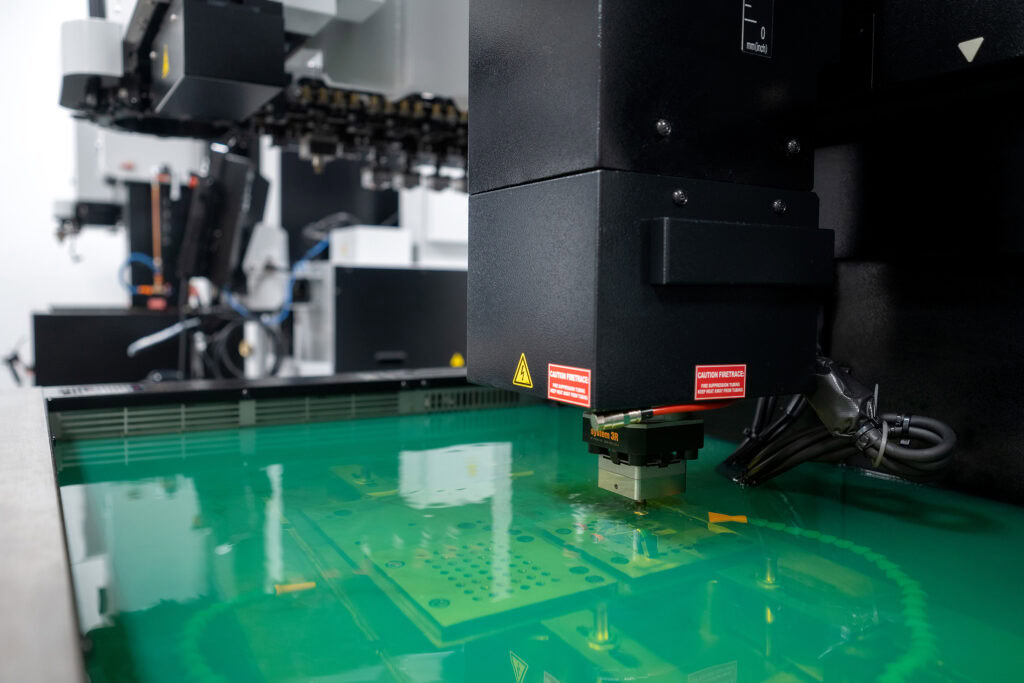

Oberg provides complete tool design and build services in-house. Our Western Pennsylvania facility features:

- 50 presses (5–400 tons) with speeds up to 1,200 SPM and beds to 145″

- Tryout capabilities in-house

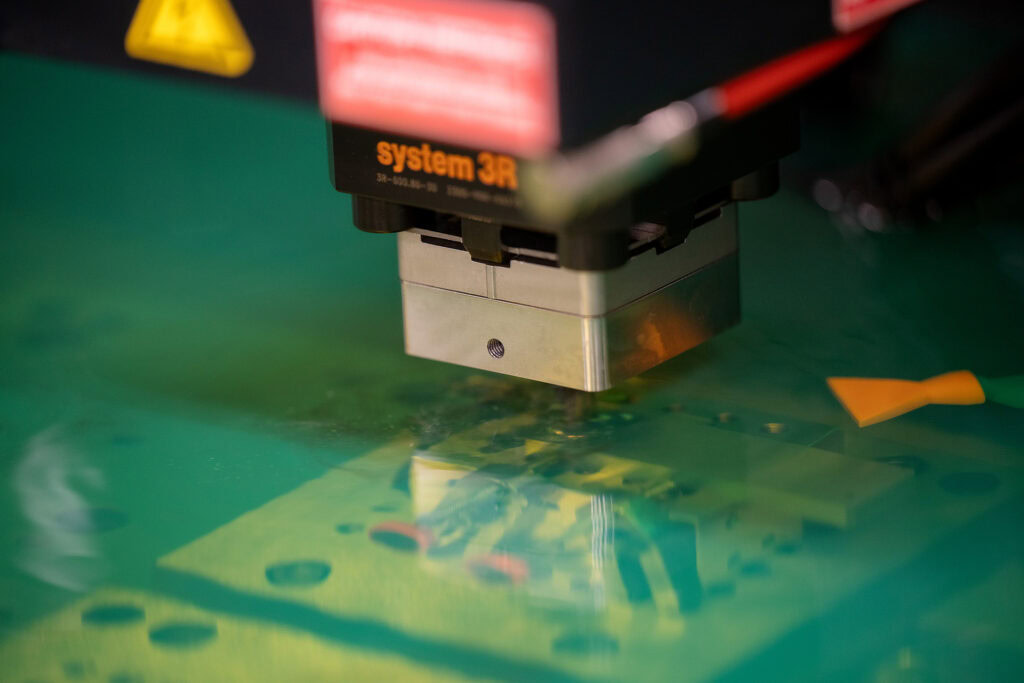

- Precision grinding, EDM, CNC machining, and tool assembly

- In-die tapping and automation-ready setups

- Long-life tooling using carbide, coated steels, and specialty alloys

- Support for heat treatment, bead blasting, and custom finishing

Tooling with Local Support and National Reach

From our Pittsburgh-area headquarters, we serve OEMs and stamping houses across the U.S. Our modular tooling solutions enable fast line changes, reduced downtime, and higher tooling ROI – backed by American-made quality and 75+ years of die-building expertise.

Modular Stamping Dies That Work as Hard as You Do

If you’re ready to optimize part variety, reduce press downtime, and future-proof your tooling investment, contact Oberg Industries. Let’s create modular stamping dies that perform – every time, every cycle.