Your Products Get To Market Faster

We can help you accelerate new products to market. Scale manufacturing into the production volumes you need. Or expand capacity for a legacy product.

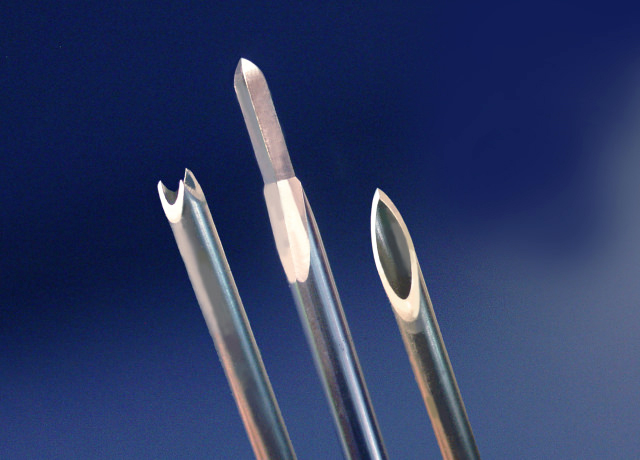

Innovation Focused

Using our design-for-manufacturing methodology, our project managers, manufacturing engineers and quality engineers collaborate with your project teams to develop high quality products that meet your customers’ needs in the most cost-effective manner and the shortest time to market.

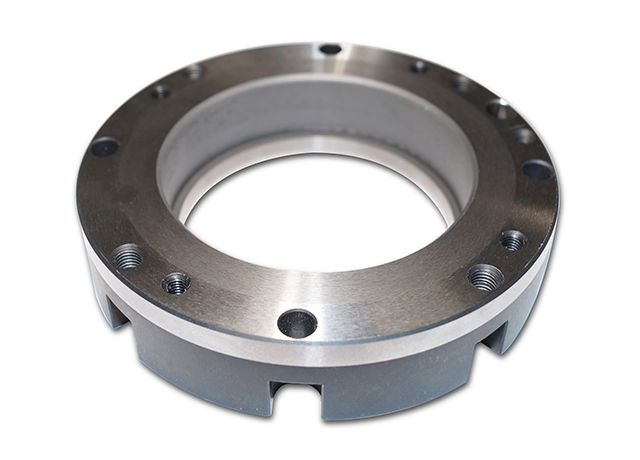

The Capacity You Need

We’ve recently expanded our manufacturing floor space by an additional 80,000 square feet and are again planning to add more capacity. Our industry leading apprenticeship program is designed to attract and develop the skilled machinists needed to support our customers. Facilities in Pittsburgh, Chicago and Costa Rica offer the people, equipment, capacity and passion to cost effectively meet your growth needs or help consolidate your supply chain.