Applications for Laminations for Lighting & Electronic Components

- Transformer & Power Systems – Core laminations for inductors, transformers, and converters

- LED & Smart Lighting – Stamped components for lighting assemblies requiring energy-efficient design

- Consumer & Industrial Electronics – Circuit-compatible laminations for thermal and magnetic optimization

Built to Perform, Engineered for Scale

Oberg delivers:

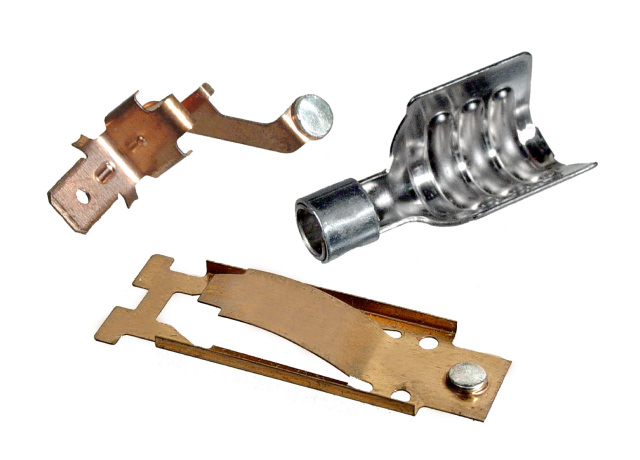

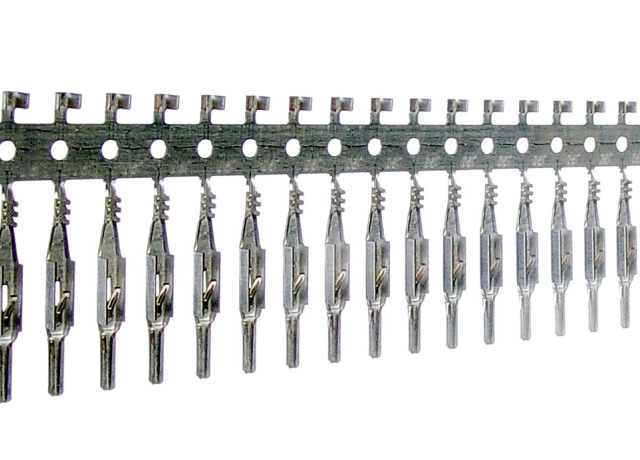

- Thin-Gauge Expertise – Laminations from materials such as silicon steel, nickel, and specialty alloys

- Material Precision – Minimal burrs, consistent stack alignment, and magnetic reliability

- Flexible Volumes – Small-batch prototyping to large-scale production without sacrificing quality

Integrated Manufacturing. Focused Results.

From our Western Pennsylvania headquarters, we provide:

- Design-for-manufacturing (DFM) support for part launches

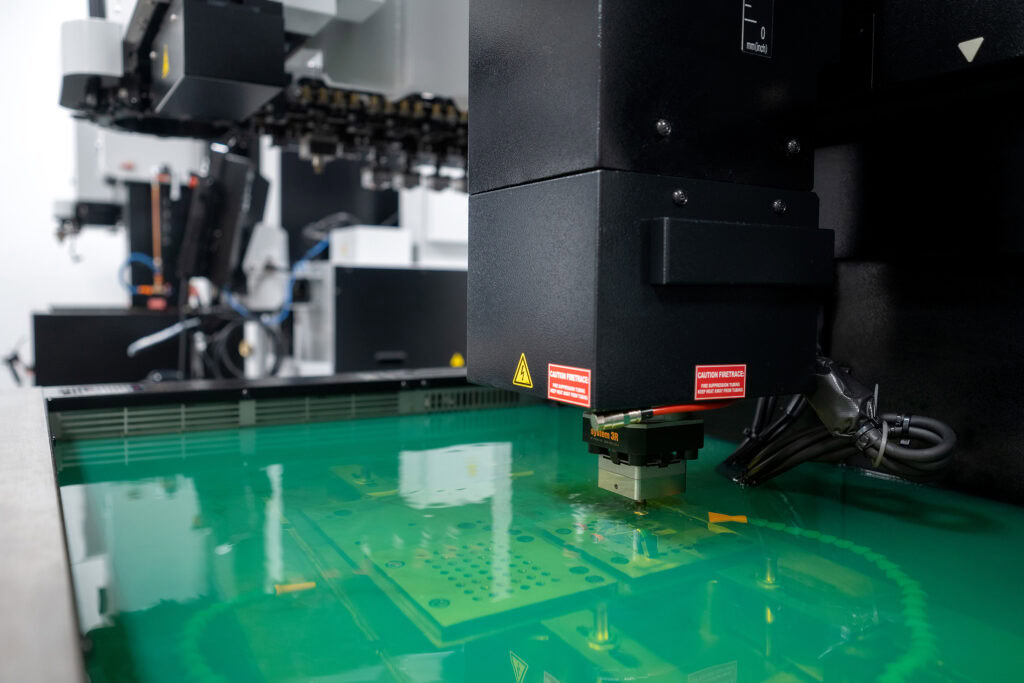

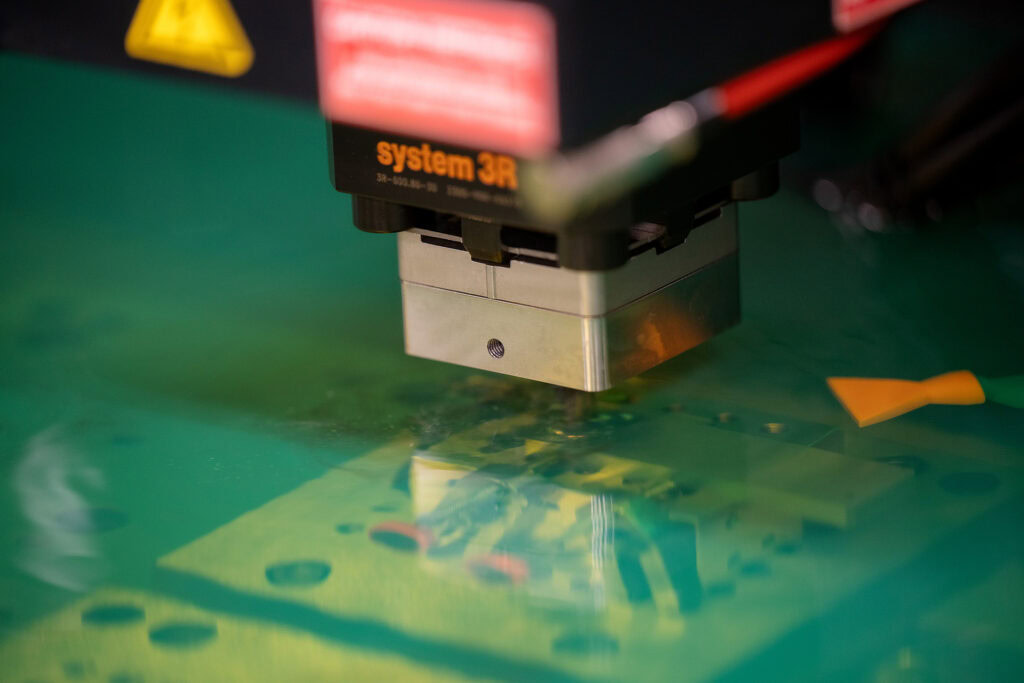

- 50 high-speed presses (5 to 400 ton, up to 1,200 SPM)

- In-house tooling design and die maintenance

- Expertise in M4–M64 electrical steels, aluminum, copper, cobalt alloys, and CO-C5 insulation materials

Lighting the Way in Lamination Innovation

Since 1948, Oberg has helped power progress in electronics through advanced stamping and tooling. We’re proud to serve lighting and electronics manufacturers across the Northeast and beyond with fast turnaround and proven reliability.

Let’s Get Your Lamination Project Moving

Contact us today to discuss your electronic or lighting lamination needs. From prototypes to full-scale production, we deliver the precision your systems demand.