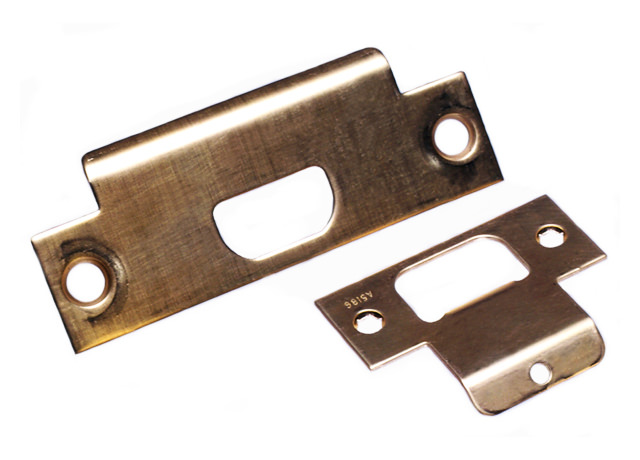

Stamped Part Production for Housing & Construction

Oberg’s precision-stamped part production capabilities support the production of:

- Door & Lock Hardware – Internal mechanisms, latch carriers, strike plates, actuator clips, and faceplates

- Window Systems – Brackets, reinforcement plates, and sash clips for residential or commercial use

- Smart Home Device Components – Mounting plates, housings, and stamped inserts for integrated home technology

- HVAC & Utility Fixtures – Stamped bases, supports, and brackets used in ducting, units, and wall systems

- Architectural Hardware – Stamped backing plates for handles, knobs, and control panels

- Custom Assemblies – Stamped to print for proprietary systems or product development initiatives

Built to Support Versatile, High-Volume Production

Our housing and construction partners benefit from:

- Progressive Die Stamping – High-speed stamped part production with consistent dimensional control

- Flexible Material Capabilities – Steel, brass, aluminum, stainless, and coated materials for diverse performance requirements

- In-House Tooling & DFM Support – Optimized stamping dies and design-for-manufacturability guidance reduce development time and cost

- Integrated Quality Systems – From first article to full production, each part is inspected to meet exacting requirements

From Concept to Production – Stamped Solutions That Scale

Oberg Industries supports domestic and international OEMs with the capacity to take on both established and emerging product lines in the construction market. Our mix of precision tooling, scalable stamping operations, and engineering collaboration makes us a preferred partner for complex and high-volume stamped part production needs.

Explore What’s Possible with Precision-Stamped Parts from Oberg

Contact us today to learn how we can support your project with tooling, prototyping, and full-scale stamping.