What Are Progressive Stamping Dies?

Progressive stamping dies combine multiple forming actions, such as cutting, bending, punching, and coining, into a single, high-speed process. These tools improve part consistency, reduce labor, and increase throughput across millions of cycles.

Key Advantages Include:

- Multi-station dies for continuous, automated part formation

- Built-in precision for tight-tolerance, high-speed production

- Interchangeable inserts for running multiple part numbers from a single die

- Ideal for modular production, with support for left/right part symmetry and variable sizing

Example: One medical stapling tool (TA Frame) produces five different part numbers by utilizing interchangeable components that allow for alternation between left-hand and right-hand versions and size variations.

Why Choose Oberg for Progressive Stamping Dies?

- Decades of Tooling Mastery – Over 70 years building dies for the world’s most respected manufacturers

- Multi-Part Die Capability – Tools built for interchangeable setups to run different part numbers

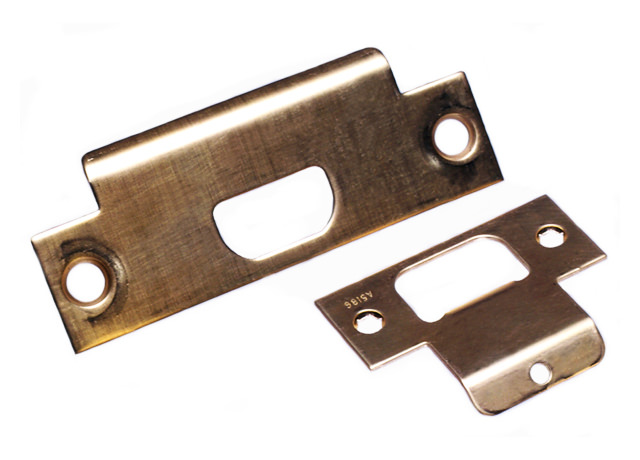

- Precision Fit and Finish – Machined to tight tolerances with high-performance materials including tungsten carbide and coated tool steels

- Support for High-Speed Systems – Designed for automation compatibility and minimized downtime

- Built to Customer Print – Dies are manufactured to exact customer specifications, with DFM support available when requested

Full-Service Tooling & Stamping Integration

- In-house stamping on 50 presses ranging from 5 to 400 tons (up to 1,200 strokes per minute)

- Press beds up to 145” for large-format production

- Material versatility, including steel, aluminum, stainless, brass, copper, and nickel alloys

- Support processes such as tapping, welding, deburring, cleaning, and assembly prep

- Die tryout, validation, and ongoing maintenance/refurbishment programs

Progressive Stamping Dies Built in the U.S. and Trusted Nationwide

Oberg’s progressive stamping dies for the housing and construction industry are trusted across the United States for their repeatability, tool life, and production consistency. We collaborate closely with OEMs, contract stampers, and integrators to build long-term success into every tool we deliver.

Start Your Next Program with Oberg

Contact us today to discover how our progressive die expertise can enhance your stamping operations in the housing and construction industries.