Click on the specific Downhole Directional Drilling Component below to learn more.

Downhole Directional Drilling Components

Downhole Assemblies

Downhole Drilling Crossovers

Gates & Seats

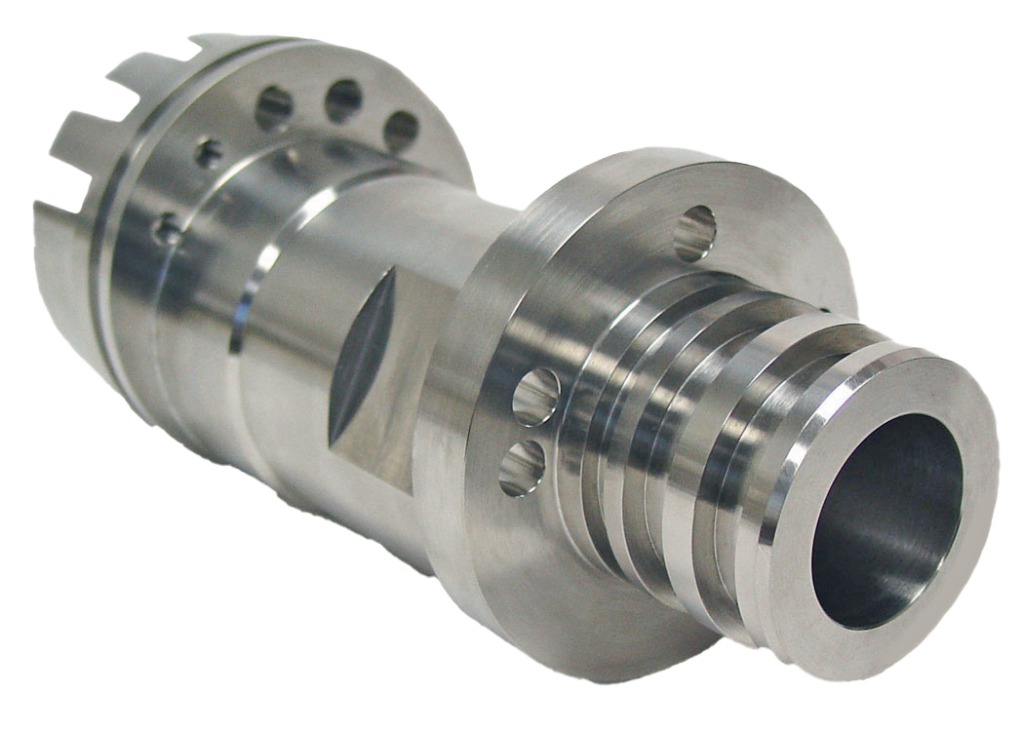

Downhole Drilling Housings

LWD Components

Manifolds

MWD

Mud Valves

Orifice Assemblies

Pulser Components

Downhole Components Refurbishment Services

Fluid Restrictors

Sample Chambers

Drilling Valves

Downhole Directional Drilling Wear Pads

Machining/Turning/EDM

Over 90 machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

Precision Grinding

Over 200 machines

- Wave Shear Grinding

- Surface / Centerless

- Jig / Advanced MDP®

- Lapping

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

- 50+ presses from 5 to 400 tons

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide

- Cobalt Alloy 6 (Stellite™)

- MP35N

- Polycrystalline Diamond (PCD)

- Titanium

- Nitronic Series

- Stainless Steel (300/400 series)

- Inconel®

- Toughmet® 3

- PEEK

Materials Used In Manufacturing Downhole Directional Drilling Components

- Tungsten Carbide: Tungsten Carbide is essential for Gates and Seats, wear pads, and restrictors, offering unmatched hardness and wear resistance. It withstands extreme pressures and abrasive fluids, ensuring long-term reliability in downhole environments.

- Cobalt Alloy 6 (Stellite™): Stellite™ is a go-to material for hardfacing Gates and Seats, mud valves, and other high-wear components. Its corrosion resistance and durability make it ideal for environments with abrasive fluids and high temperatures.

- MP35N: MP35N’s strength, ductility, and resistance to corrosion and hydrogen embrittlement make it perfect for springs, fasteners, and pulser assembly components exposed to high-pressure and corrosive conditions.

- Polycrystalline Diamond (PCD): PCD is indispensable for cutting tools and drill bit inserts, offering unparalleled hardness and abrasion resistance to reduce downtime and improve precision in challenging drilling operations.

- Titanium: Lightweight yet strong, Titanium is frequently used in housings and restrictors for downhole tools. It resists corrosion and handles high-pressure conditions with ease.

- Nitronic Series: Nitronic alloys provide exceptional strength and resistance to galling, making them a reliable choice for components like fasteners and housings exposed to abrasive fluids.

- Stainless Steel (300/400 series): Used for general components like housings and assemblies, stainless steel offers a balance of strength, corrosion resistance, and cost-effectiveness in downhole environments.

- Inconel®: This superalloy is commonly used for springs, seals, and high-temperature components in downhole tools. Its resistance to extreme heat and corrosion ensures durability in high-pressure environments.

- Toughmet® 3: This copper-nickel-tin alloy provides excellent wear and corrosion resistance, making it ideal for bearings, bushings, and other load-bearing components in downhole systems.

- PEEK: PEEK is a lightweight, high-performance polymer used in sealing components and housings for its ability to withstand extreme temperatures and chemical exposure.

Why Partner With Oberg Industries For Downhole Directional Drilling?

Our downhole directional drilling components are manufactured to provide the highest level of reliable performance in the oil & gas industry.

- Proven Expertise: With decades of experience, we understand the intricacies of manufacturing reliable, directional drilling components for the oil & gas industries.

- Precision-Driven Results: Designed and manufactured to perform at the highest level in the harshest environments.

- Global Reach: With knowledgeable sales and support representatives based in North America and Europe, we ensure responsive service and guidance for our customers worldwide.