Built for Locking System Manufacturers

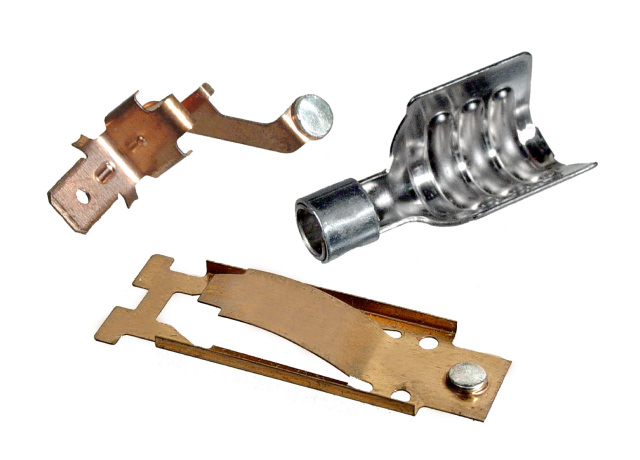

We don’t design the parts or tools – we manufacture them to spec. Our expertise lies in precision stamping and machining for components that require tight tolerances, reliable surface finishes, and seamless integration into assembly processes.

Whether you’re producing mechanical locks, electronic access systems, or custom commercial security solutions, we deliver the consistency and scale required for success.

Applications We Support

- Mechanical Door Lock Hardware – Pins, tumblers, lock plates, drive cams, cylinders, and housings

- High-Security Commercial Hardware – Robust components designed to resist wear and tampering

- Keyless Entry Systems – Mounting plates, stamped carriers, and smart lock components

- Automotive Security – Door lock components for OEM and Tier 1 security suppliers

- Custom Brackets & Mounts – Stamped hardware used in smart lock housings and control enclosures

Why Work with Oberg?

- Over 60 years of door lock component manufacturing experience

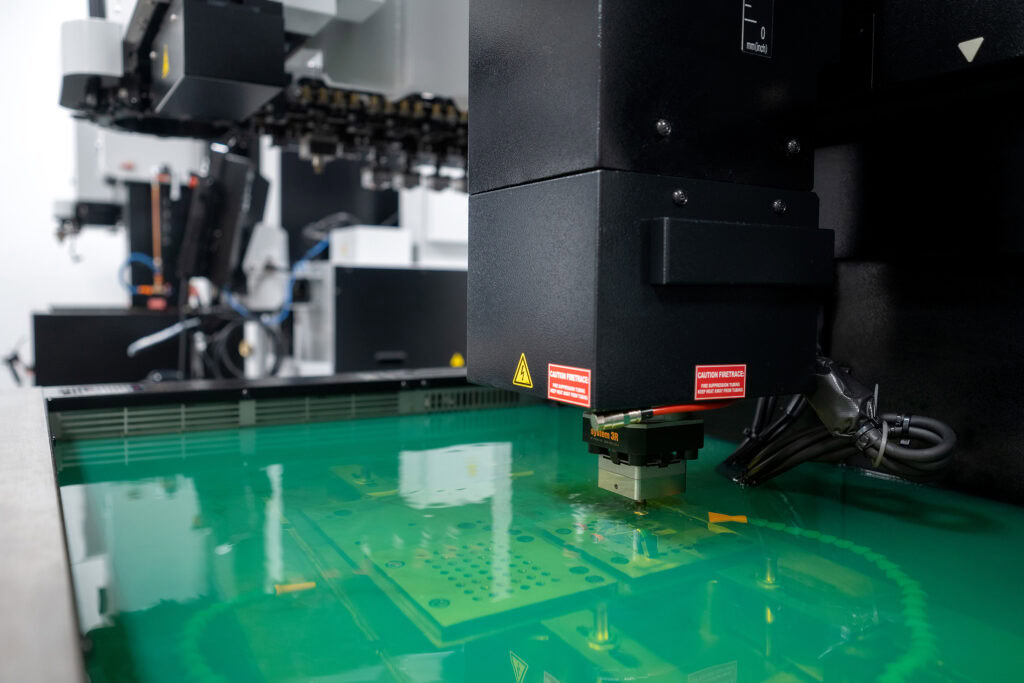

- Integrated tooling and production for end-to-end control

- Interchangeable die components for multi-part tooling flexibility

- Ability to stamp high-finish and buffing-ready materials

- Trusted source for build-to-print stamped and machined security hardware

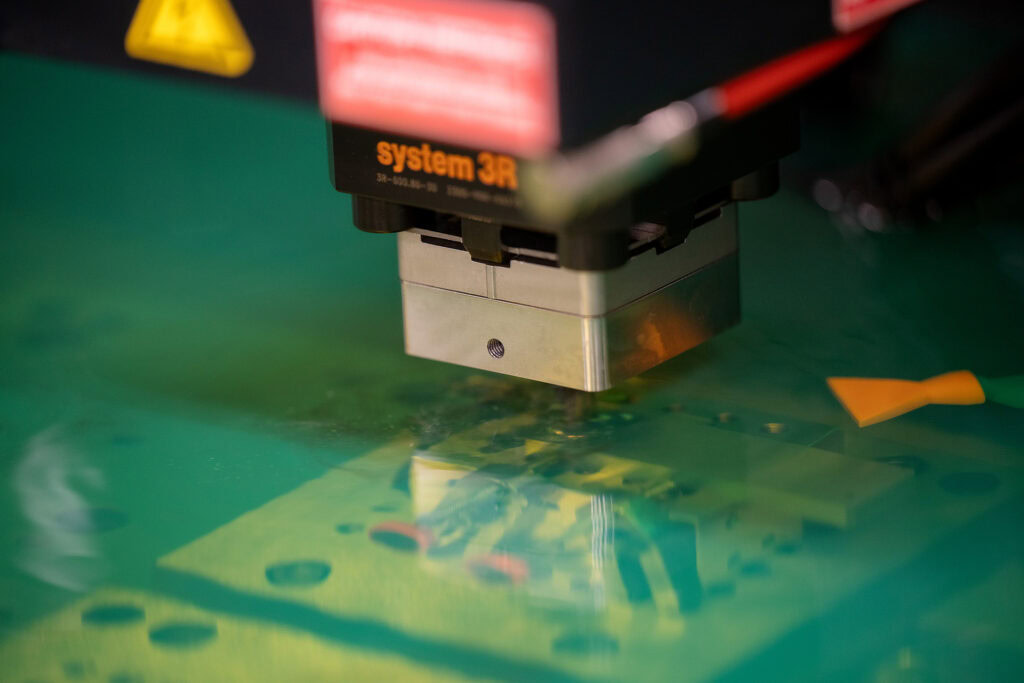

Expanded Capabilities for Demanding Applications

- Precision Machining – For components requiring complex geometries and tight dimensional control

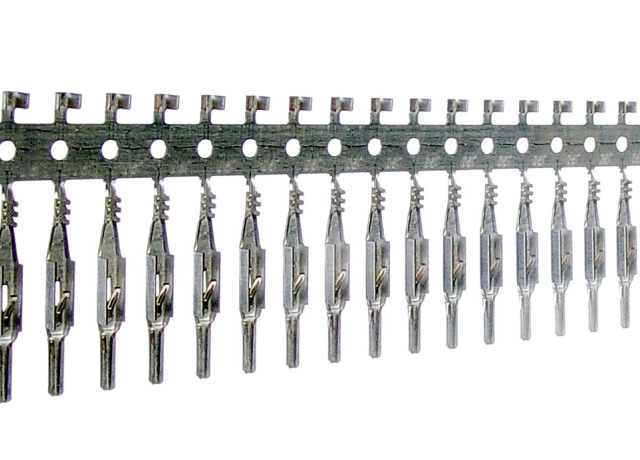

- Progressive Die Stamping – High-speed output with repeatable quality

- In-Die and Secondary Tapping – Optimized for production flexibility and cost efficiency

- Surface Treatment Support – Validated finishing partners for wear-resistant coatings and corrosion protection

- Stamping Coated Materials – Reducing or eliminating the need for secondary finishing by stamping materials ready for final polish or assembly

Material Range & Production Versatility

We work with a variety of materials, including brass, stainless steel, carbon steel, aluminum, copper, and specialty alloys commonly used in the door lock hardware industry. Our facility supports:

- 50 stamping presses ranging from 5 to 400 tons

- Bed sizes up to 145 inches

- Speeds up to 1,200 strokes per minute

- Short-run, prototype, and high-volume programs

- Custom tooling built and serviced in-house

Serving the Northeast and Beyond

While our central facility is located in Western Pennsylvania, just north of Pittsburgh, many of the door lock hardware components we produce are exported across North America and internationally.

Start with Security, End with Precision

From concept to production, Oberg Industries delivers precise and scalable solutions for the door lock hardware and other access control hardware markets.

Whether you need short-run prototyping, fully integrated stamping dies, or long-run part production, we’re ready to support your next locking system program.

Contact us today to discover how we can assist you in achieving your door lock hardware performance, quality, and delivery objectives.