Supporting Cutting Blade Manufacturers

Our role is to produce precision tooling and blade components for high-performance cutting blades. Whether you’re developing personal care products, surgical tools, or industrial knives, Oberg delivers reliable solutions that enhance production efficiency and product quality.

Cutting Blade Applications Served:

- Consumer Goods – Razor blades and components for shaving, blades for household items, and appliances

- Medical – Components for surgical instruments and specialized medical cutting devices

- Industrial – Tooling and blades for automation and high-volume production systems

- Packaging & Food – Blade components used in clean-cutting, high-speed environments

Work with Oberg for Cutting Blades

We manufacture build-to-print tooling and blade components to your exact designs.

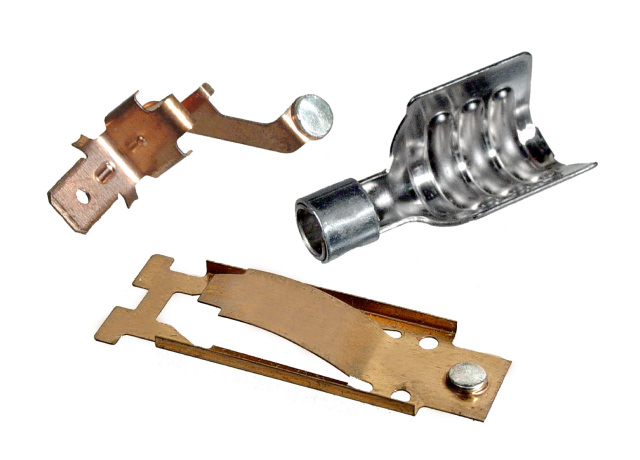

- Specialized Material Expertise – Including tungsten carbide, stainless steel, and other wear-resistant alloys

- Versatile Manufacturing – Support for manual, automated, and high-speed cutting platforms

- Trusted by Industry Leaders – Decades of experience in high-tolerance tooling and part production

From Tooling to Prototype to Production, Oberg Can Deliver:

- Precision Grinding – Tight tolerances and uniform finishes

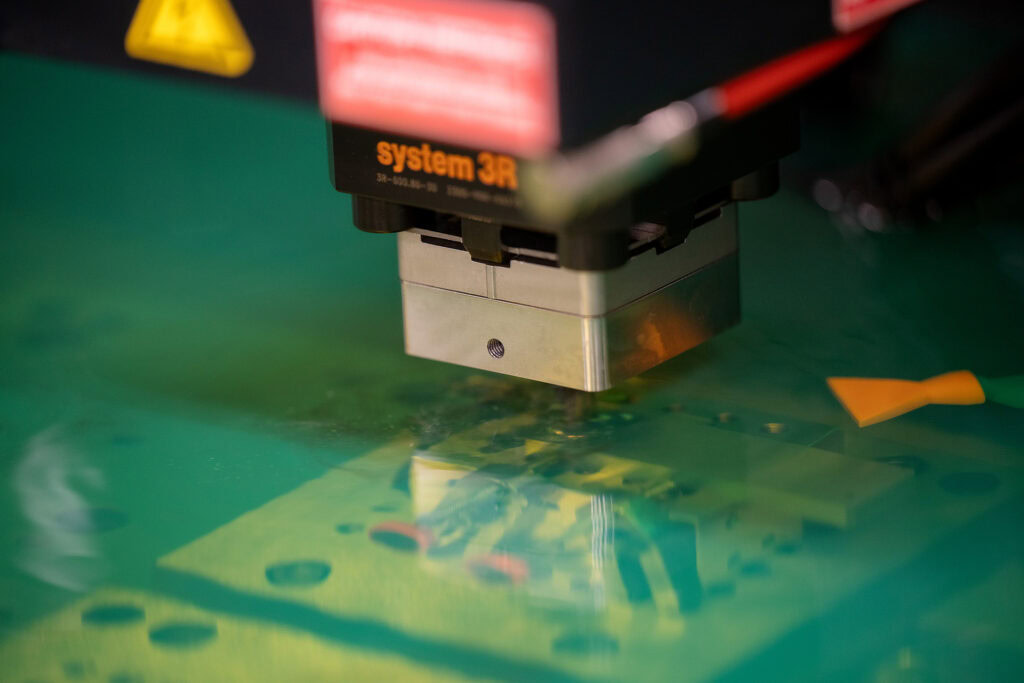

- Precision Machining – To exact specifications

- Performance Coatings – (Upon request) Improve longevity and reduce operational wear

- Scalable Capacity – Production flexibility

Cutting Blade Production Capabilities to Match Your Needs:

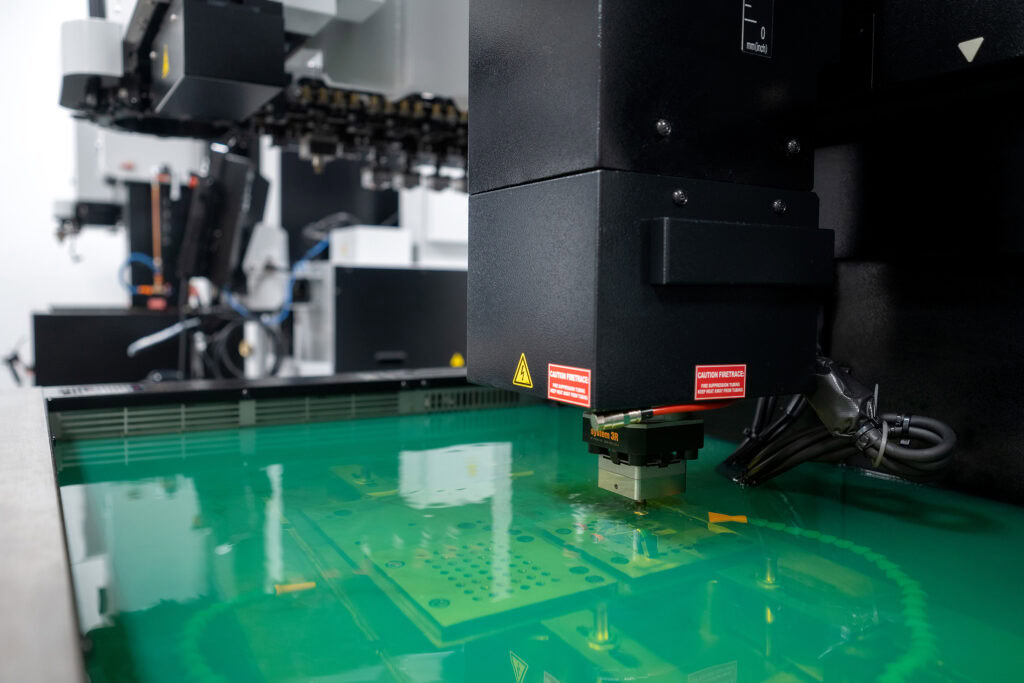

Looking to take your cutting blade design into production? From prototype to full-scale production in one facility, our Pennsylvania location features this and more, all under one roof:

- 100,000 sq. ft. facility dedicated to tooling design and precision metal stamping

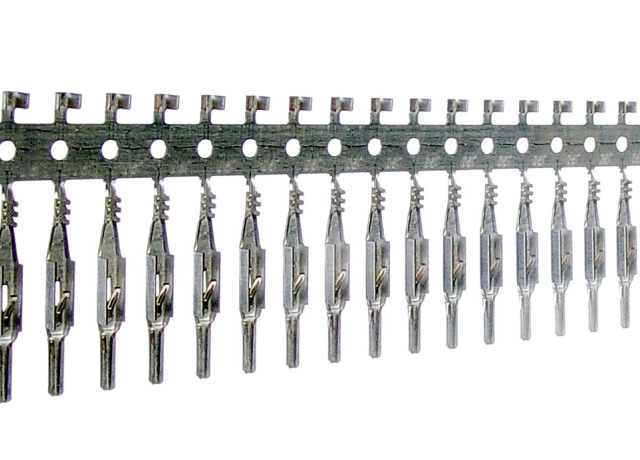

- Design and manufacture carbide and steel progressive stamping dies

- Prototype metal stamping

- Automated and manual product assembly

- Stamping technology development

- Expertise in an array of metals: Aluminum, brass, bronze, cold-rolled steel, copper, Inconel®, Hiperco® 50, nickel, cobalt alloys, silicon electrical steel, stainless steel

- 50 stamping presses, 5–400 ton, running at speeds up to 1,200 SPM

- Hard-working and highly experienced workforce

Proudly Based in Western Pennsylvania

Oberg Industries serves customers across the Northeast U.S. and beyond. Our proximity offers fast lead times and the assurance of American-made quality.

Your Edge Starts Here

With a strong foundation in high-precision tooling and build-to-print manufacturing, Oberg Industries delivers cutting blade solutions built to perform.

Contact us to explore how our capabilities can support your blade production goals.