Stamping Capabilities to Meet Complex Stamped Parts Demands

Our team supports production programs through every stage of development:

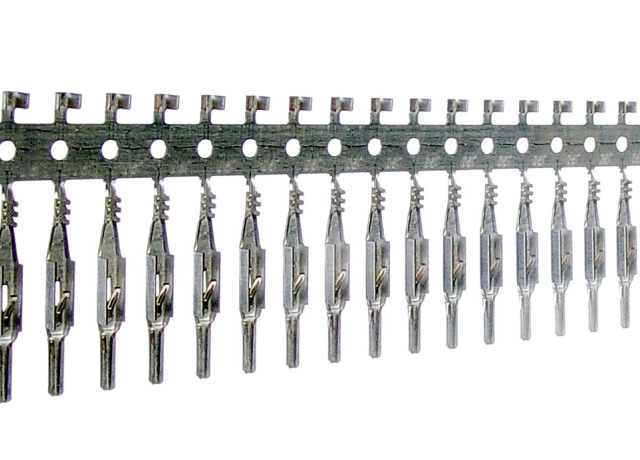

- High-Speed Progressive Stamping – Multi-stage, tight-tolerance stamping for consistent results at scale

- Single & Multi-Lam Stamping – For electric motors, transformers, and stator/rotor assemblies

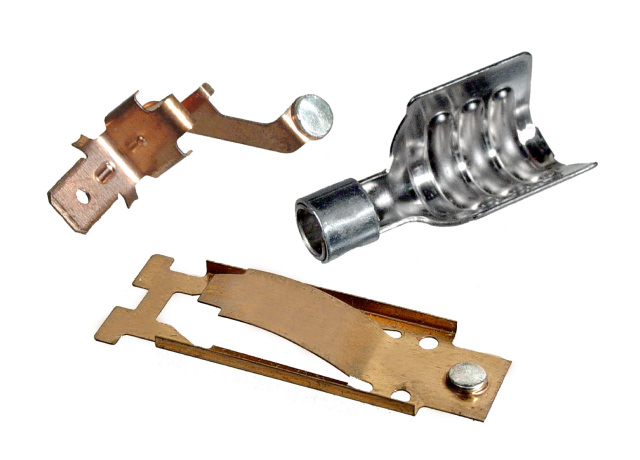

- Deep Draw & Complex Forming – Custom tooling for intricate stamped parts requiring structural strength and unique shapes

- Insertion & Coining Stamping – Electrical contacts and hybrid stamped parts with integrated wires or conductive inserts

- Custom Die Manufacturing – Built in-house for streamlined prototyping, tryout, and long-run performance

Industries & Part Types

Oberg’s stamped parts are manufactured to print and support critical functions across:

- Automotive & EV/HEV – Battery tabs, bus bars, motor laminations, terminal inserts

- Energy & Power Generation – Rotor/stator laminations, generator frames, mounting structures

- Consumer Products & Tools – Appliance brackets, hand tool blades, enclosures, and housings

- Medical Devices – Surgical staples, bone plates, knife blanks, cleanroom-ready stampings

- Electronics & Connectors – Lead frames, terminals, shields, and contact points

- Construction Hardware – Lock components, hinge plates, latch carriers, and architectural fittings

- Industrial Automation – Sensor brackets, drive components, smart device hardware

- Aerospace & Defense – EMI shielding, precision housings, structural clips, and brackets

Tooling & Quality Assurance for Long-Term Production

Oberg’s complete in-house stamping solution is backed by tool design, manufacturing, and robust quality control protocols:

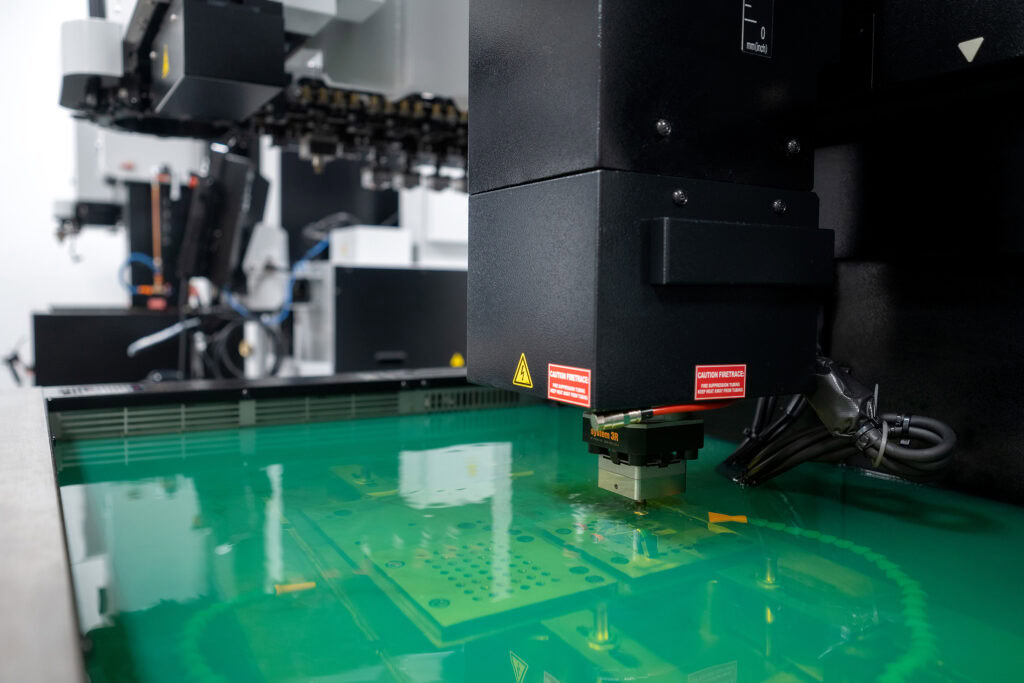

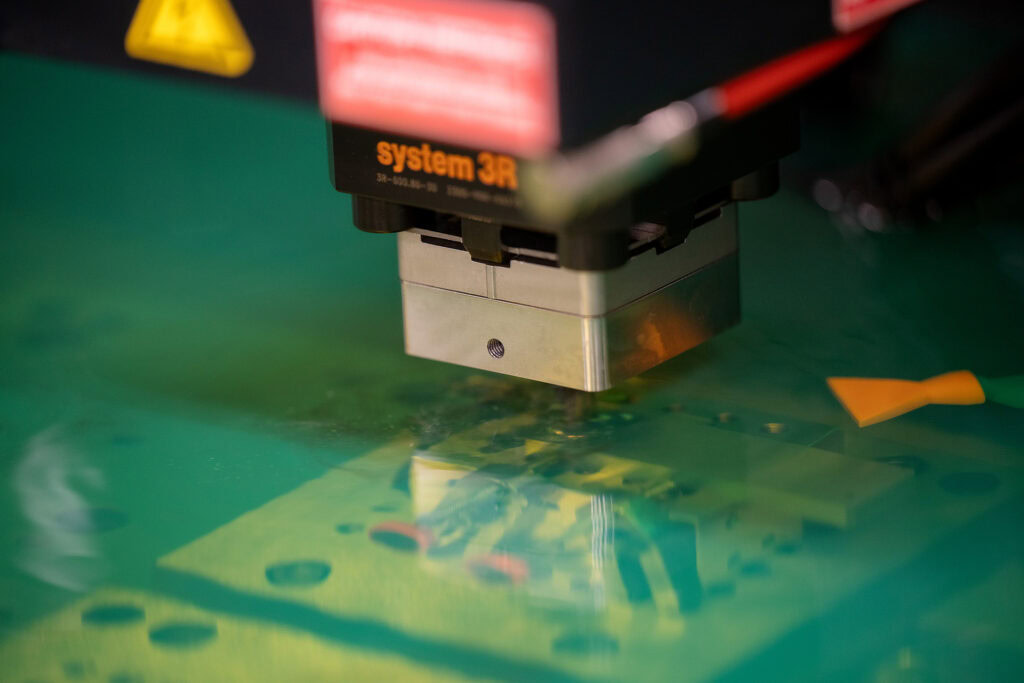

- Tooling & Die Manufacturing – Optimized for manufacturability and efficient press performance

- High-Volume Stamping Lines – Designed for continuous production of millions of units with minimal variation

- Advanced Metrology & Inspection – Including automated systems like CMMs, OGP SmartScopes, optical comparators, and contact-based probing systems

- Validation & Repeatability – Dimensional checks at every step to maintain customer specs across long production runs

Build Your Stamping Program with Oberg

From prototype to production, Oberg Industries helps companies launch and scale stamped parts programs with confidence. With a reputation for precision and a commitment to quality, we’re ready to support your next tooling or production requirement.

Contact us today to discuss your stamped parts project and discover what’s possible with Oberg’s integrated manufacturing solutions.