Hand Tool Applications & Capabilities:

- Laminated & Locking Pliers – Stamped or machined in layers for strength and durability

- Cutting Tools & Blades – Engineered for wear resistance, sharpness, and repeatability

- Surgical & Specialty Instruments – Machined to meet medical-grade finishes and tight tolerances

- Gripping & Fastening Tools – Customer designed ergonomic components built to support high-load performance

Why Oberg for Hand Tool Manufacturing

- Complete Tooling Integration – In-house design and build of the tooling that forms your products to your specs

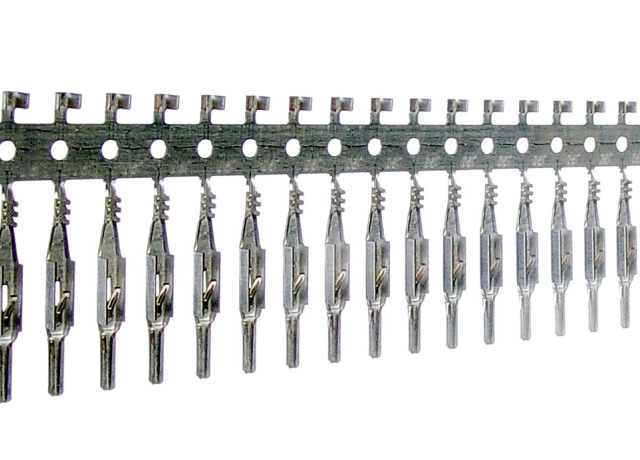

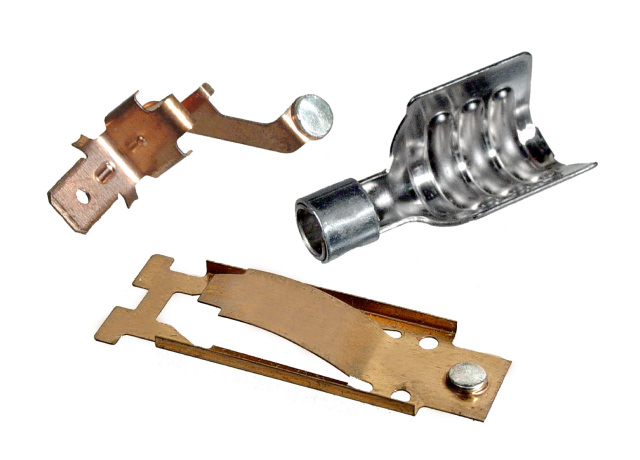

- Advanced Production Methods – From CNC machining and Swiss turning to high-speed stamping

- Material Mastery – Experience with tool steels, stainless, and coated alloys

- From One-Off to Mass Production – Full scalability across product lifecycles

Built to Endure. Made to Scale.

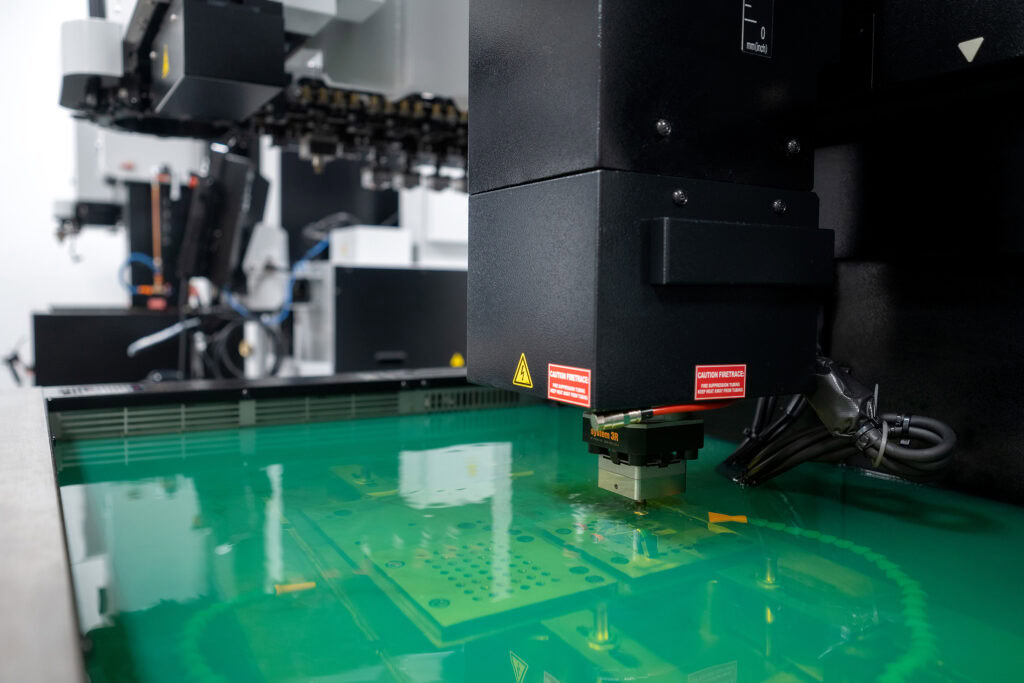

Operating from our 100,000 sq. ft. stamping and tooling facility in Western Pennsylvania, Oberg Industries delivers:

- 50 presses from 5 to 400 tons operating up to 1,200 strokes per minute

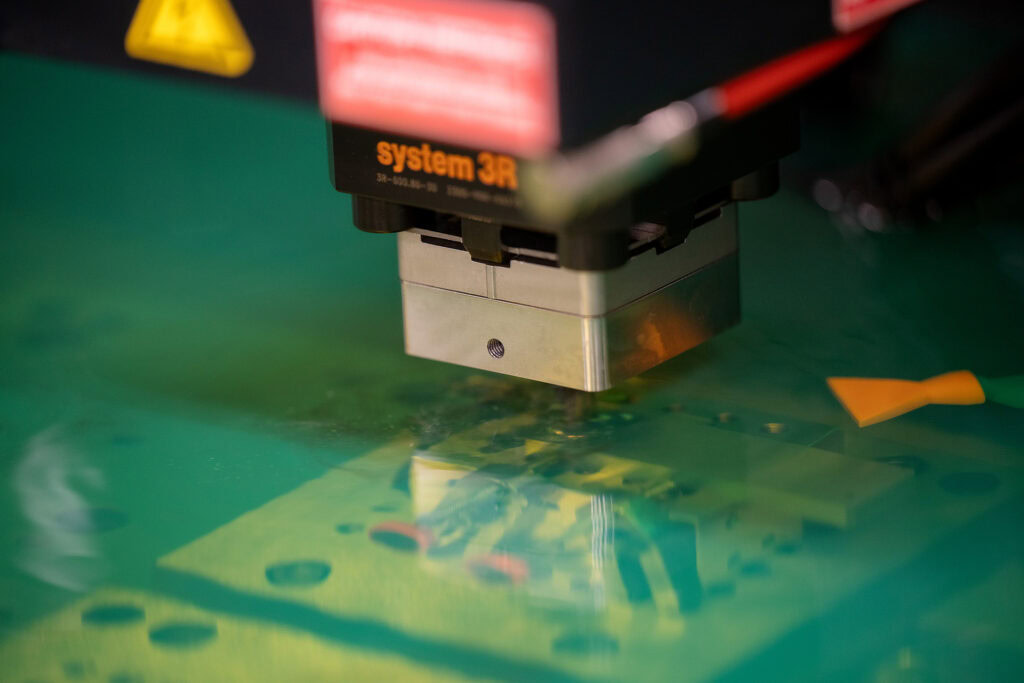

- Multi-axis CNC machining centers, EDM, and automated grinding

- Clean and durable finishing capabilities, including cryogenics and surface prep

- Short-run prototyping and full-scale production—under one roof

From Pennsylvania to Production Lines Nationwide

With locations just north of Pittsburgh, Pennsylvania, as well as in Chicago, Illinois, we partner with hand tool brands across the Northeast and beyond. Our U.S.-based facilities ensure fast turnarounds, dependable quality, and long-term supply chain confidence.

Hand Tool Production. Crafted to Perform. Delivered to Excel

Whether you’re launching a new tool or scaling a legacy product, Oberg Industries provides the hand tooling and parts you need to lead the market.

Contact us today to learn how we can support your hand tool production goals.