Applications We Support:

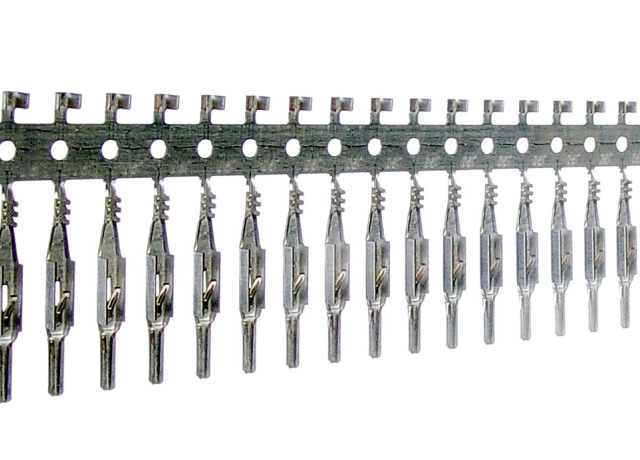

- Fiber Optic Connectors – Tooling to produce, high-precision data connections

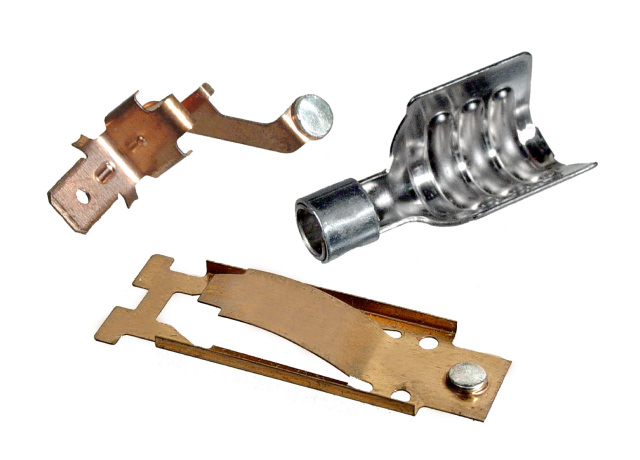

- Ferrules, Sleeves & Splice Tooling – Micro-machined tooling for signal alignment and low insertion loss based on customer designs

- Fiber Optic Bushings – Tools that taper glass fibers to final cable dimensions while preserving structural integrity

- Micro-Components – Aerospace, defense, and medical-grade fiber optic tooling

- Customized Assembly Tooling – Fixtures and support for complex fiber optic assembly lines

Built for Accuracy and Signal Integrity

When precision matters, our tooling is trusted for:

- Micro-Tolerance Alignment – Maintaining precise core alignment

- Material Versatility – Designed to process a variety of metals; stainless steel, brass, engineered polymers, and exotic alloys

- Repeatable Results – Whether for prototyping or high-volume production

Advanced Machining Backed by Specialized Services

Located in Western Pennsylvania, Oberg supports U.S. and International fiber optic manufacturers with a blend of core and specialty services:

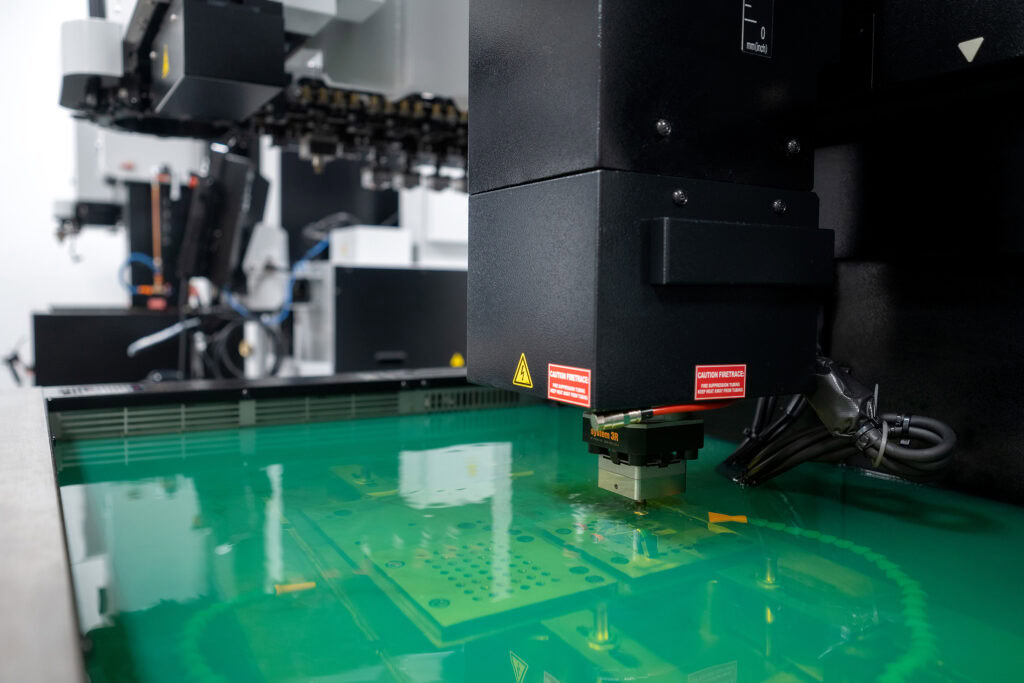

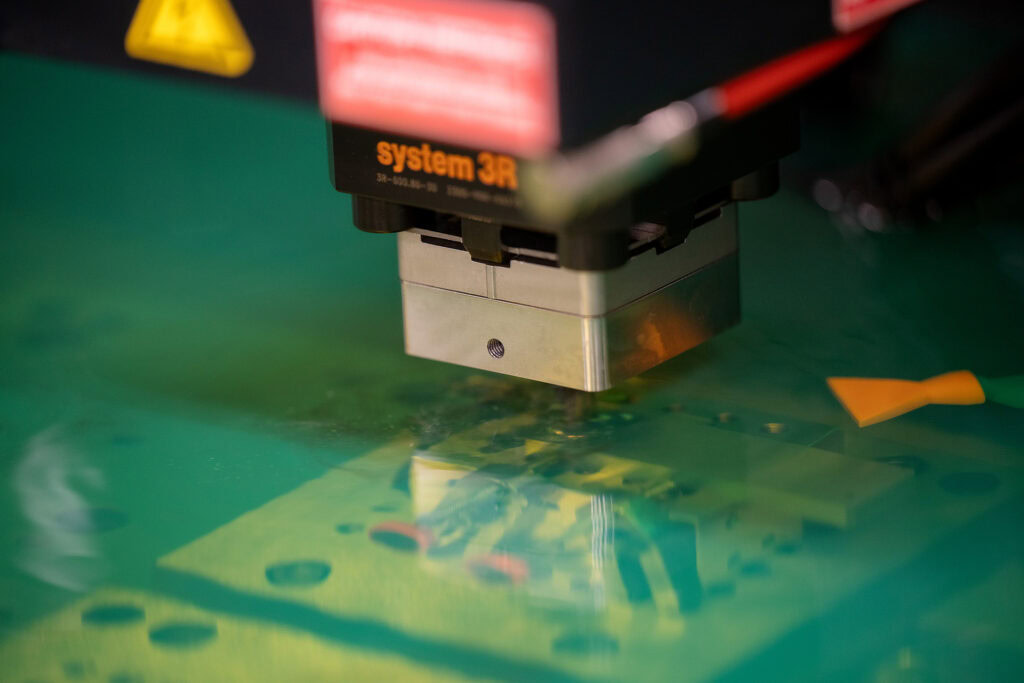

- Multi-axis machining and turning for ultra-fine features

- EDM and fine-surface grinding for critical tolerance tooling

- FOBA laser marking and part ID for traceability in assembly lines

- Heat treatment, passivation, and bead blasting for tool longevity

Your Partner for Optical Innovation

With over 75 years of tooling leadership, Oberg Industries brings unmatched precision to fiber optic tooling. Whether supporting fast-paced telecom builds or long-lifecycle defense systems, we deliver:

- Tight-tolerance, build-to-print tooling

- Micro-dimension control for fiber-critical applications

- Full design-for-manufacturing (DFM) support during part launch

Let’s Build the Tools that Power Your Signal

Contact us today to discuss your fiber optic tooling needs. From ultra-compact fixtures to full-process tooling, we’re ready to support your success in the connected world.