Applications We Support

- Automotive & EV Powertrains – Rotors and stators for hybrid and electric vehicle motors

- Power Generation Systems – Components for turbines, generators, and transformers

- Industrial Automation – Robotics, machine tools, and high-efficiency servo motors

- Aerospace & Defense – Lightweight, high-output drive systems

- Consumer Electronics – HVAC units, compressors, and appliance motors

Engineered for Magnetic Efficiency and Stack Precision

Every electric motor lamination program at Oberg is built for accuracy, repeatability, and electrical performance:

- Tight-tolerance stamping for minimal burrs and consistent stack geometry

- Lamination thicknesses down to 0.008″, diameters from 0.375″ to 49″

- Optimized for low core loss and superior magnetic alignment

- Rotational skewing capabilities for improved efficiency and balance

- Insulating lamination stamping (e.g., G9 Melamine Glass Cloth, Nomex®) for dielectric separation

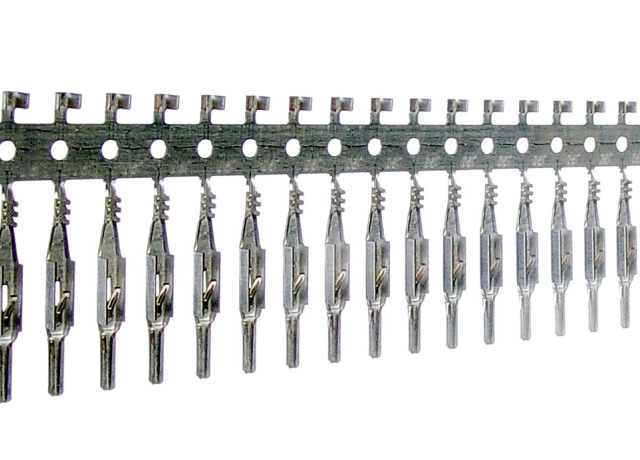

In-Die Interlocking Capabilities

Oberg’s interlocking technologies are a key differentiator for electric motor production:

- Laminations are interlocked directly in the die using automated tooling controllers

- Individual lams are rotated and skewed during stacking for enhanced balance

- Slide and actuator systems allow for varied lam geometries to be included within the same stack

- No adhesives or post-stacking steps required – saving time and reducing labor

This in-tool process produces stable, balanced rotor and stator stacks ideal for high-speed motor applications.

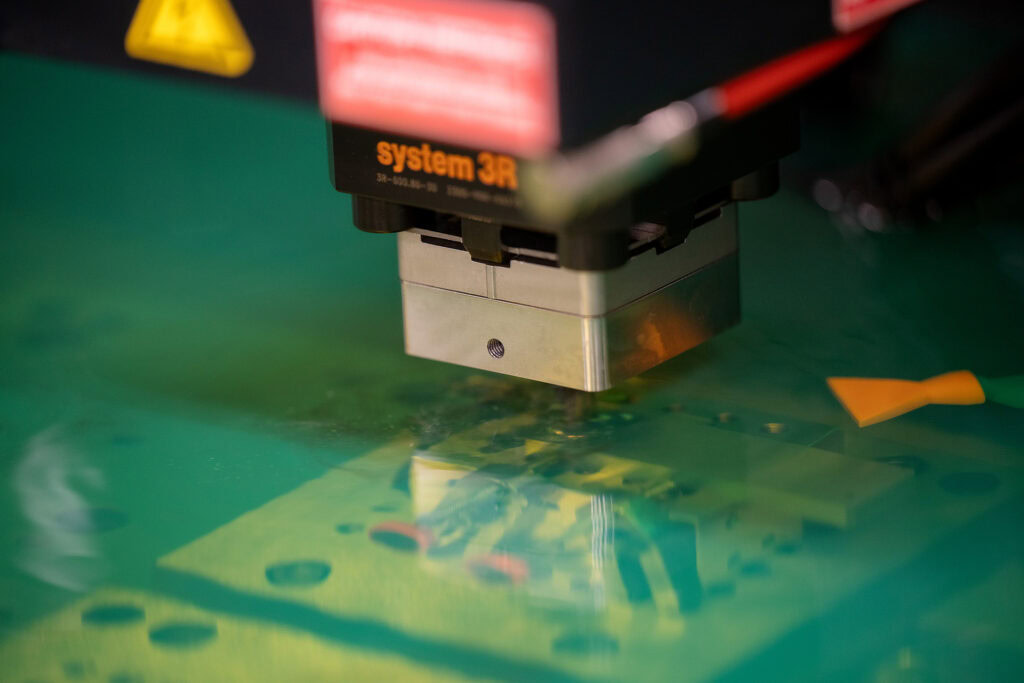

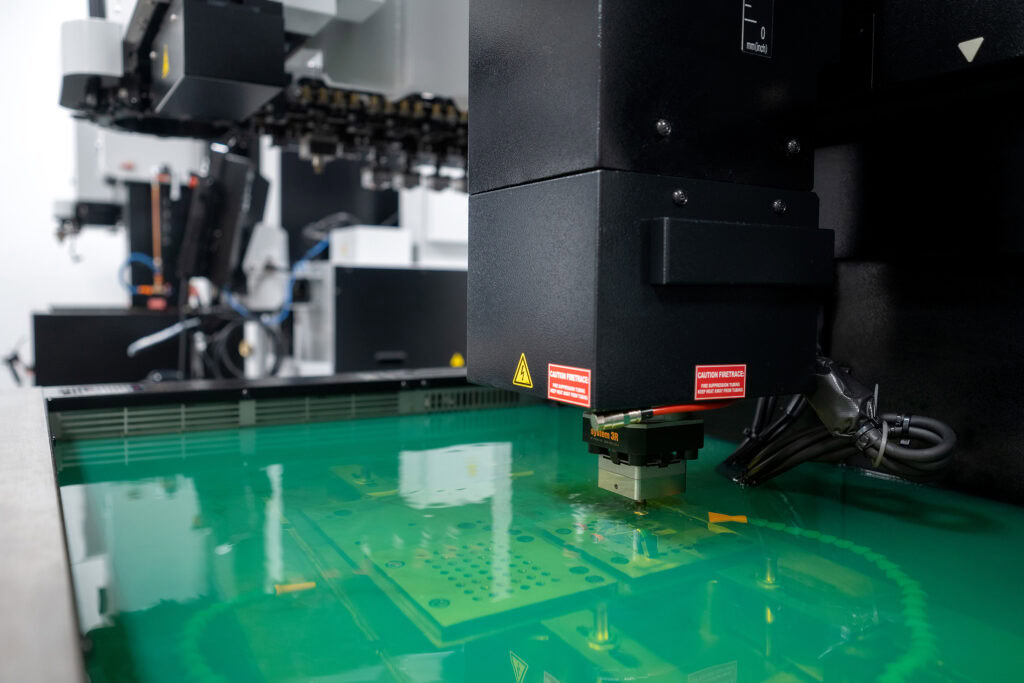

Tooling and Production Built for Scale

From tooling design through production stamping, our U.S.-based facility delivers:

- Progressive carbide and steel lamination dies engineered in-house

- Up to 1,200 strokes/minute and bed sizes up to 145″

- 50+ presses ranging from 5 to 400 tons

- Integrated die maintenance and refurbishment programs

- In-house prototyping and tryout support for new programs

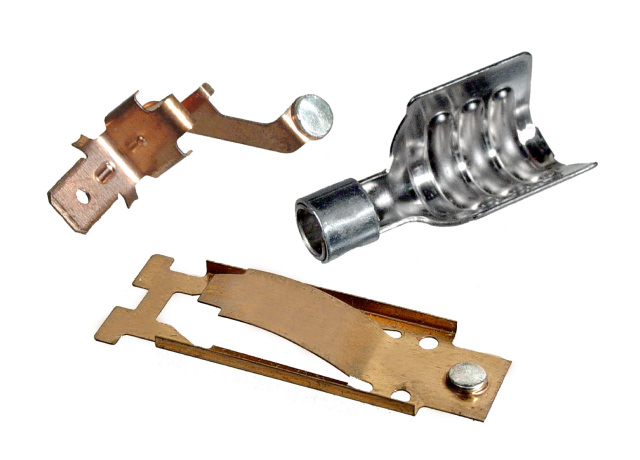

Material Range

Oberg’s material expertise supports both conductive and insulating applications:

- Electrical steels (M4 through M64)

- Cobalt alloys, nickel alloys, Hiperco®, Vacodur®, Carp 49®

- Copper and aluminum for high-efficiency systems

- Insulation-grade materials including G9 Melamine, Nomex®, and specialty composites

Complete Electric Motor Laminations Support

Our vertical integration includes a full suite of secondary processes to support lamination stack prep and motor system integration:

- Cryogenics and stress relief

- TIG and laser welding

- Cleaning, deburring, and surface prep

- FOBA cosmetic laser marking

- Final inspection with advanced CMMs, OGP systems, and optical comparators

Partner with Oberg for Electric Motor Laminations Excellence

From single-lam prototypes to millions of interlocked rotor and stator stacks, Oberg Industries delivers the tooling and precision to power your next-generation electric motor program.

Contact us today and learn how our extensive experience in deep motor lamination, automation capabilities, and stamping quality make us a trusted supplier for critical motor systems worldwide.