Proven Capabilities Ready for Your Thermal Hardware Designs

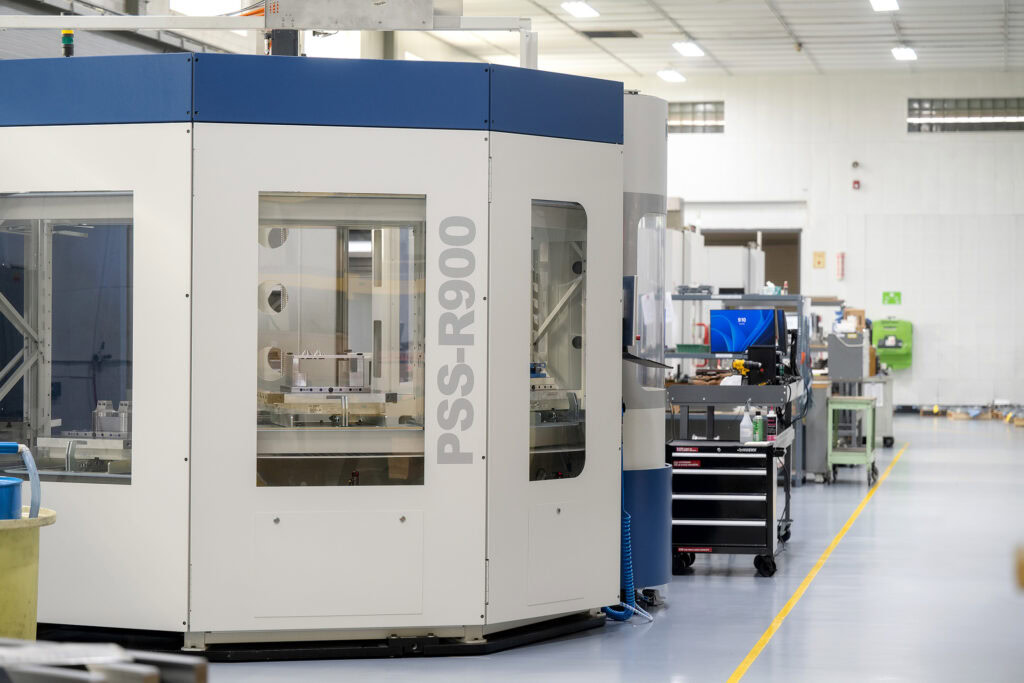

Oberg Industries has the expertise and equipment to manufacture spacecraft radiators, heat sinks, and other thermal components to customer-supplied specifications. Our processes are equipped to support customer programs where consistent flatness, precision machining, and repeatability are essential.

If your team is developing new thermal management hardware, Oberg is equipped to support your build with the same precision and consistency required across aerospace and space applications.

Thermal Hardware We Are Equipped to Manufacture

- Pocketed aluminum heat sinks for avionics cooling

- Multi-surface radiator segments for thermal dissipation

- Thermal interface plates and spreaders for component integration

- Lightweight frames and brackets for radiator mounting assemblies

Our Machining Maximizes Thermal Performance

Every edge, groove, and surface contact point matters when it comes to managing heat. Our precision machining processes ensure that thermal components are manufactured to specification with dimensional accuracy and surface quality to support functional requirements.

- 5-axis machining and pocket milling for weight and surface control

- Expertise in materials, such as: Aluminum, Copper, Invar, Titanium

- Our Polishing and surface prep to enhance thermal contact

- CMM validation of contact faces, flow paths, and mounting geometry

- We provide Design for Manufacturability (DFM) support to help customers streamline production and maintain engineering intent.

Your Designs. Manufactured with Precision

Oberg does not design thermal systems, we machine and validate them based on your drawings. Every edge, groove, and interface is produced to the specifications you engineer, with documented inspection for qualification and confidence in orbit.

We are Ready to Support Your Thermal Build

Whether you need a one-off prototype or a production run of thermal assemblies, Oberg provides the machining capacity, metrology, and workforce expertise to manufacture your hardware as designed.

Contact us today to discuss how Oberg can support your spacecraft radiator and thermal component requirements.