Below are examples of Rocket and Spacecraft Components we can manufacture for our customers.

Contact us and let’s discuss your specific needs.

Rocket / Spacecraft Components

Propulsion & Launch Components

Landing Components

Ground Support Products

Rocket Engine Components

Fuel System Fittings

Satellite Components

Payload

Solar Panel Frames

Instrument and Sensor Housings

Antenna Components

Sensor Housings

Optical Instrument Mounts

Thermal Management Components

Heatsinks & Radiators

Other Structural Components

Frames & Chassis

Brackets & Mounts

Panels & Enclosures

Design for Manufacturing and Design for Assembly (DFM/DFA)

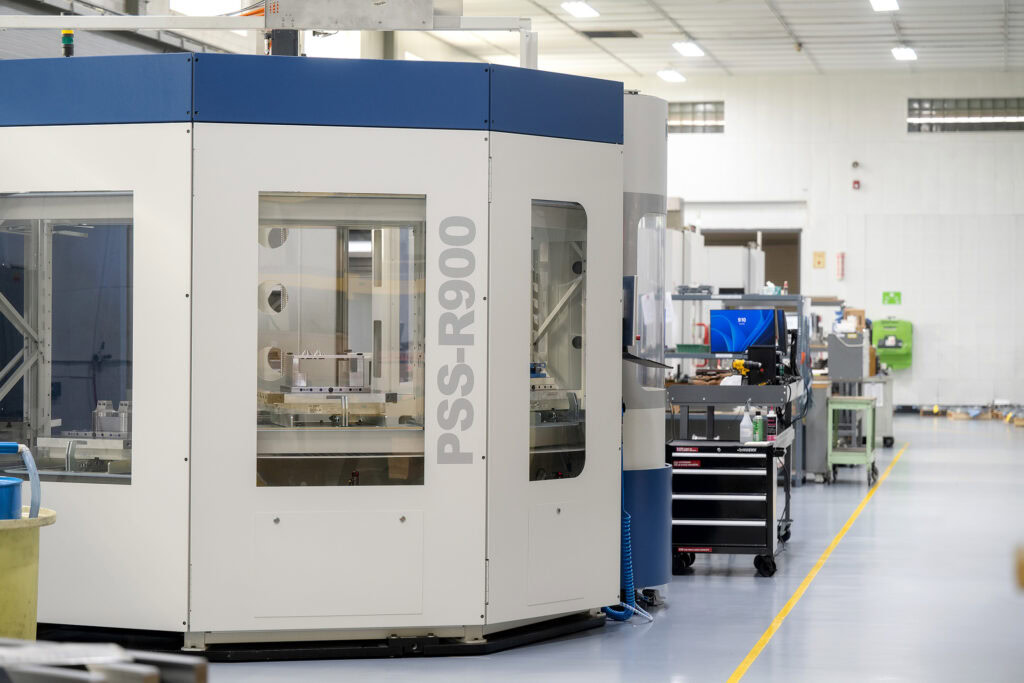

Machining/Turning/EDM

- Multi-Axis Milling – 3/4/5-axis

- Large Part Machining – 3/5-axis

- Turning

- Hard Turning Lathes

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn (Chicago plant)

Precision Grinding

- Surface / Centerless

- OD & ID (multi-axis grinding)

- Lapping / Polishing

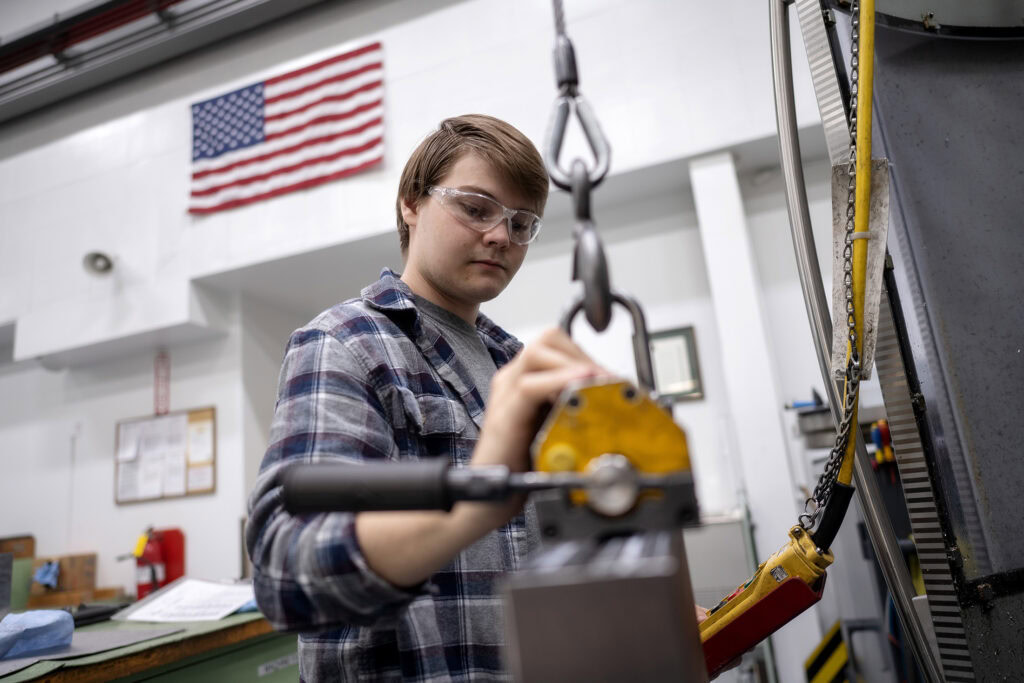

Assembly Cells

- Full automation

- Kitting, Packaging, Labeling

Special / Secondary Processes

- Heat Treating – vacuum heat treating and heat treating ovens

- Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- CMM Inspection

- Validated Special Processes

- Vision Systems

Quality

- AS9100

- An understanding of DFAR

- Validation experience

Program Management – SPOC

- Inconel®

- Molybdenum

- Nickel

- 300 series Stainless

- 400 series Stainless

- Nitronic 50

- Nitronic 60

- Titanium

- Aluminum

- A286

- 15-5

- 4140

- 4340

- A514

- A572

- 13-8

- Copper

- Delrin®

Oberg offers a complete line of standard size and custom manufactured tungsten carbide punches, matrixes and pilots in imperial and metric dimensions/tolerances. Oberg carbide die components can be manufactured to your print or drawing, regardless of shape or size. Oberg’s precision carbide stamping die components and tooling are recognized by manufacturers around the world for unmatched durability and quality.