A 70-Year Track Record

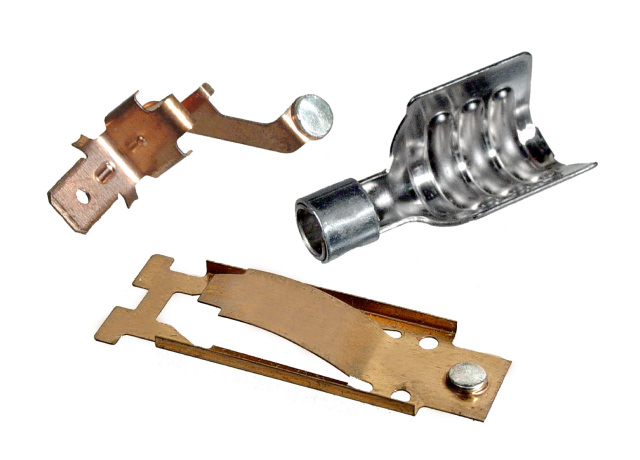

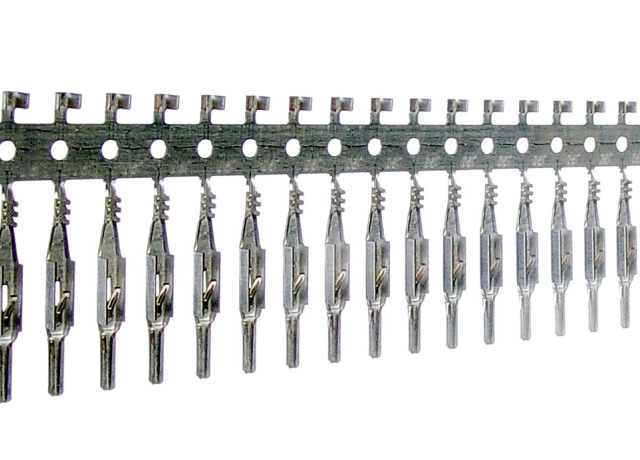

Oberg has decades of experience in designing and manufacturing high-precision, high-volume progressive stamping dies. We consistently produce products of exceptional quality, meeting promised lead times and increasing production volumes to meet your needs.

Collaborative Spirit

Our project managers, manufacturing engineers and quality engineers partner with your team to creatively solve existing production issues or to increase your existing production volumes.

Attention To Detail

Whenever extreme precision is demanded, Oberg is up to the task. We’re known for manufacturing products like coin blanks, saw blades and plastic blanks for credit cards. We produce the minute holes in the thin metal used in lighters. And our proprietary grinding technologies sharpen faster and better than traditional techniques.