Experienced Talent

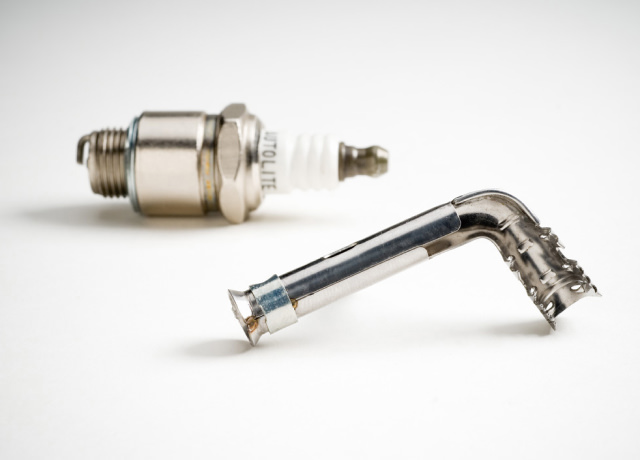

With our tooling design engineers, automation engineers and over 450 machinists, technicians, and press operators, we’re pros at providing cost-effective solutions for high volume, precision automotive applications.

Tooling Innovators

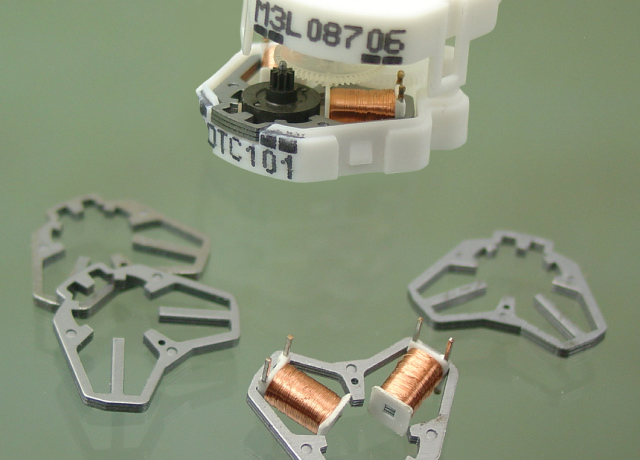

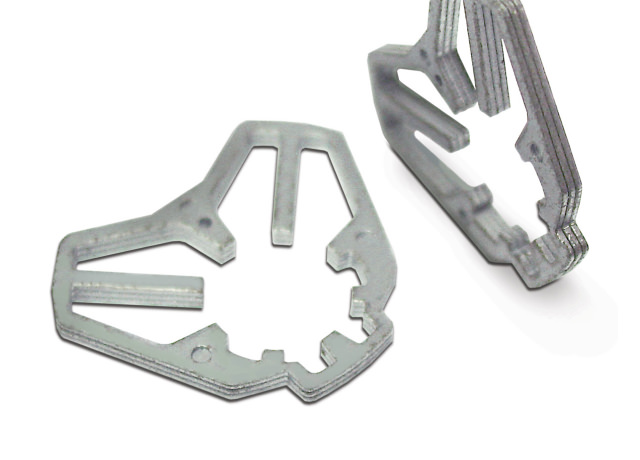

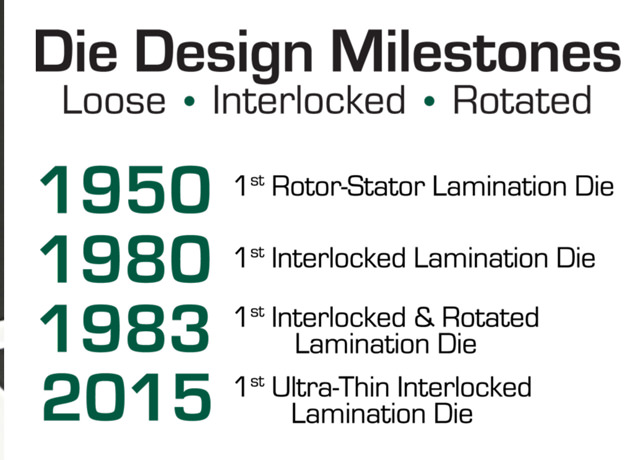

Over 50 years ago, Oberg pioneered the integration of tungsten carbide in stamping dies with continued innovations in design and efficiency. Still leading the way, our new EV/HEV try-out cell is designed to test our next-generation stamping dies that produce lamination stacks composed of ultra-thin material for the EV and HEV market.

Capacity When You Need It

We’re equipped to handle high-volume programs and multi-tool stamping transfer programs. Our project managers and manufacturing engineers can accelerate your programs and include fastening, finishing, in-process