Design and Engineering Support

Carbide Analysis Lab Support

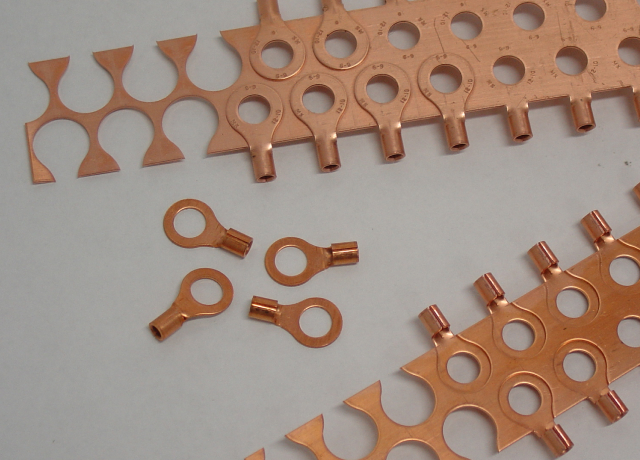

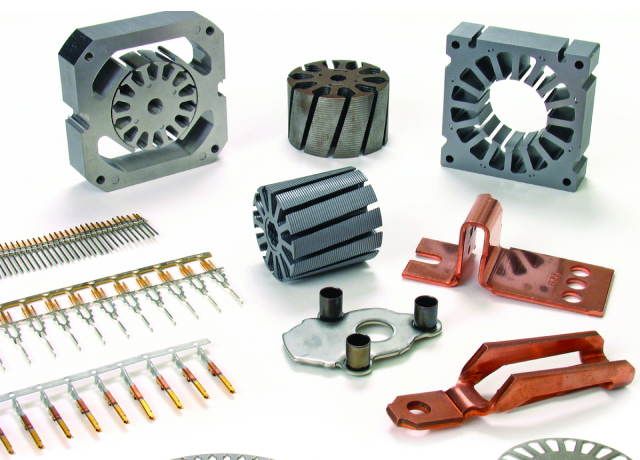

Production Stamping

- 50+ presses from 5 to 400 tons

Machining/Turning/EDM

Over 250 machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

Precision Grinding

Over 200 machines

- Surface / Centerless

- Jig / Advanced MDP®

- Wave Shear Grinding

- Lapping

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

Assembly Cells

- Semi-automated

- Tungsten Carbide

- Stainless Steel

- Tool Steels

- Ceramics

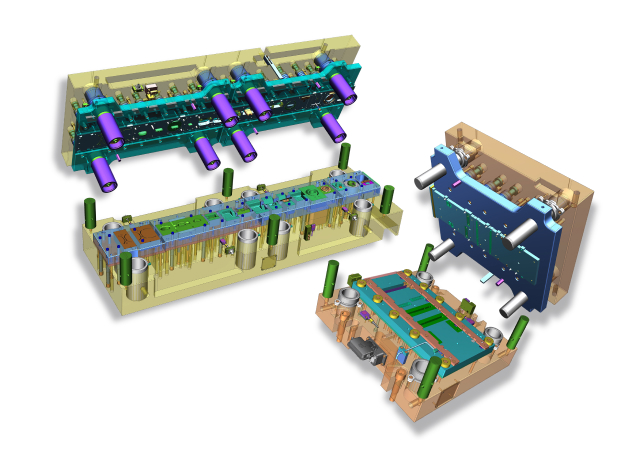

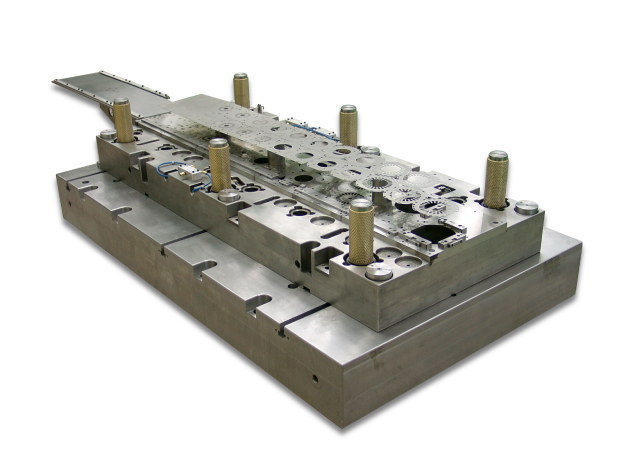

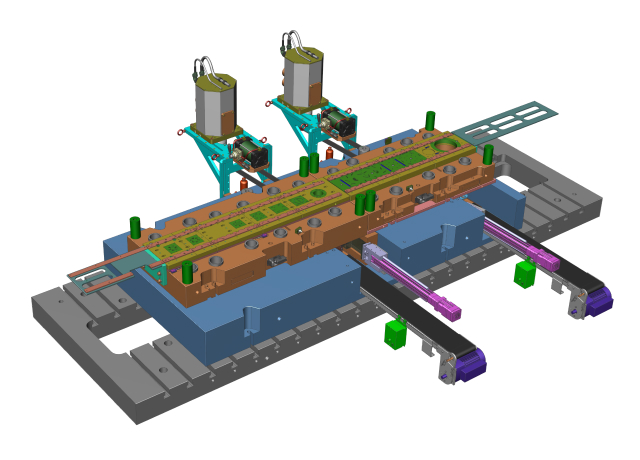

- Tungsten Carbide Progressive Stamping Dies

- Modular Stamping Dies

- Slot Dies

- Prototype Tooling

- Electric Vehicle Rotor and Stator Dies

- Dies for brittle material or fiber material

- Rotor Stator dies

- EV/HEV Thin Lamination Dies

- Stamping Die Replacement Parts

- Small-Hole tooling

- EDM Powerfeed Tooling

- Primary + Secondary Scroll Dies

- Alterations, repairs, servicing

- Automation for Tooling Systems

- Punches and Bushings

Oberg offers a complete line of standard size and custom manufactured tungsten carbide punches, matrixes and pilots in imperial and metric dimensions/tolerances. Oberg carbide die components can be manufactured to your print or drawing, regardless of shape or size. Oberg’s precision carbide stamping die components and tooling are recognized by manufacturers around the world for unmatched durability and quality.